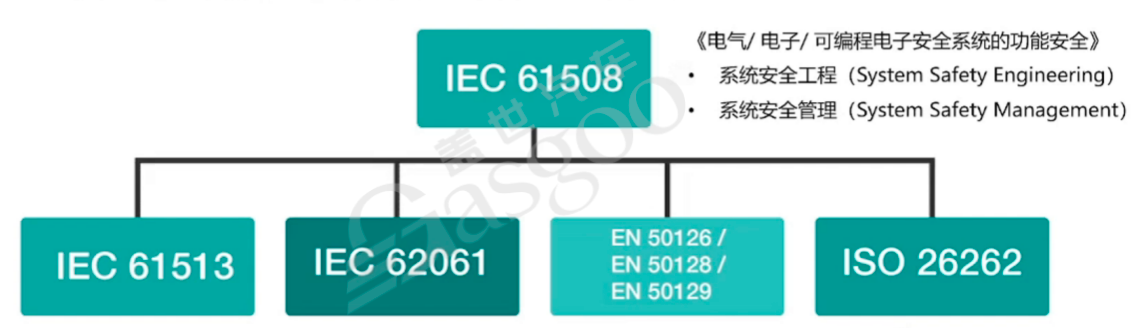

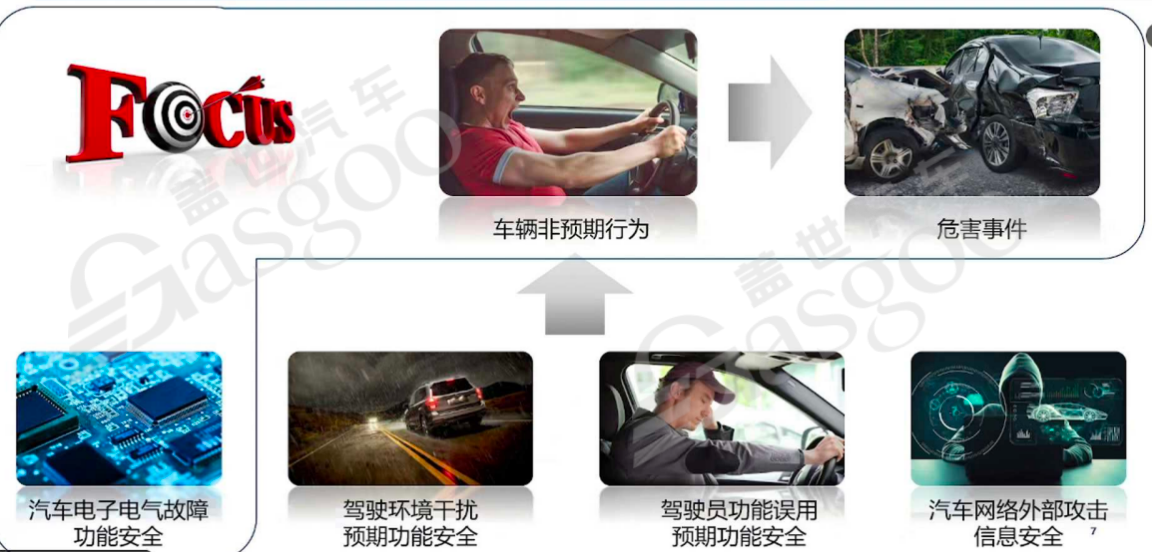

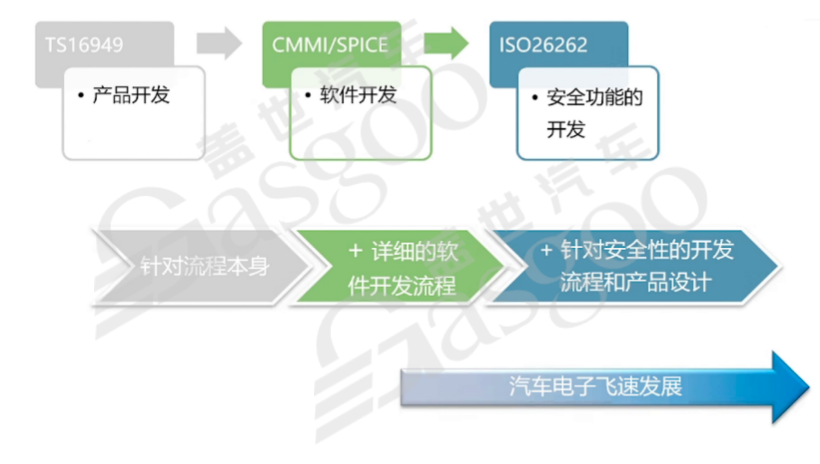

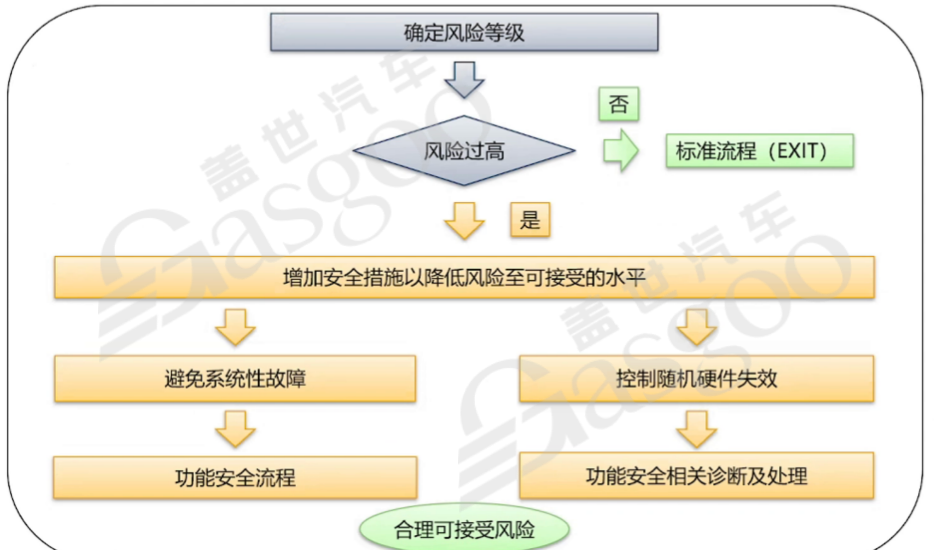

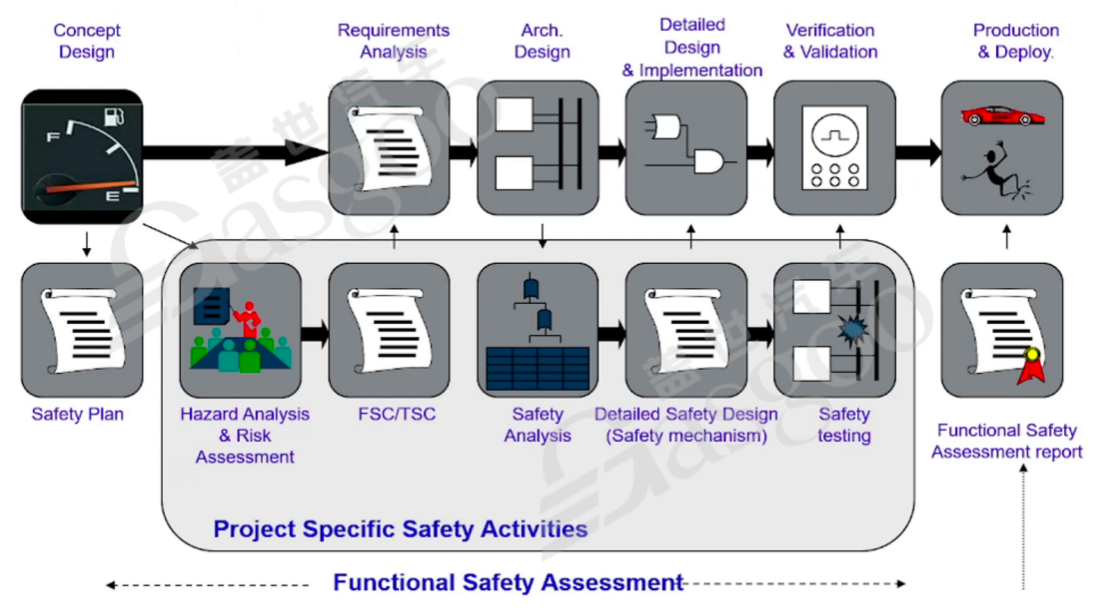

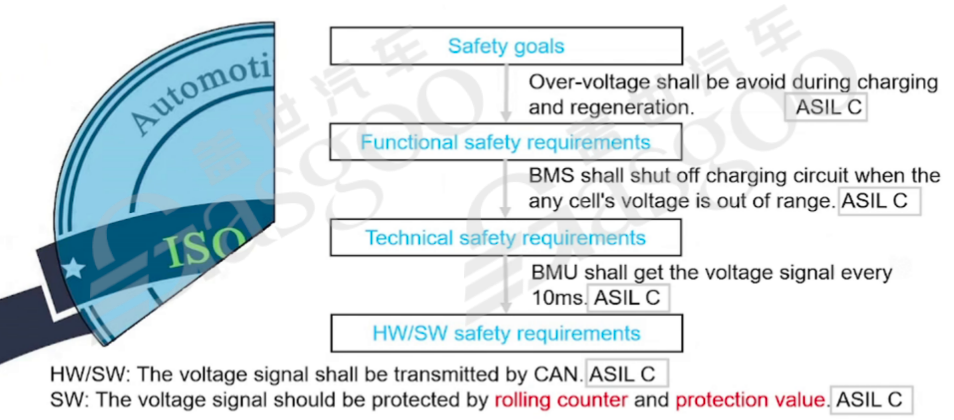

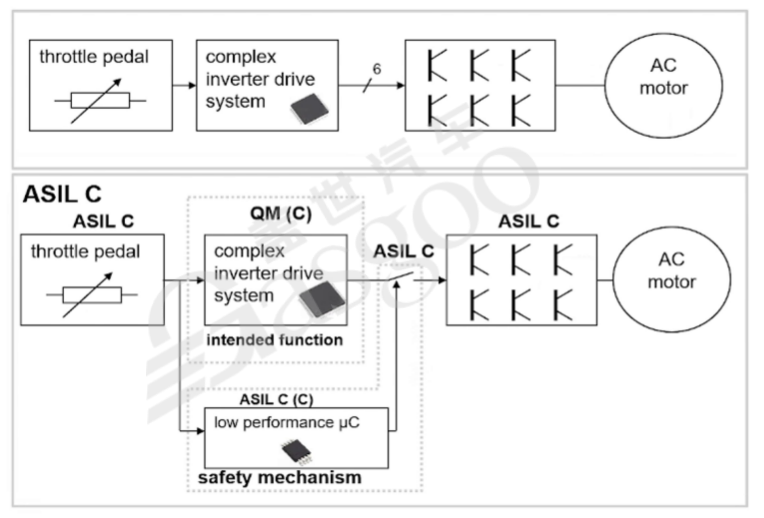

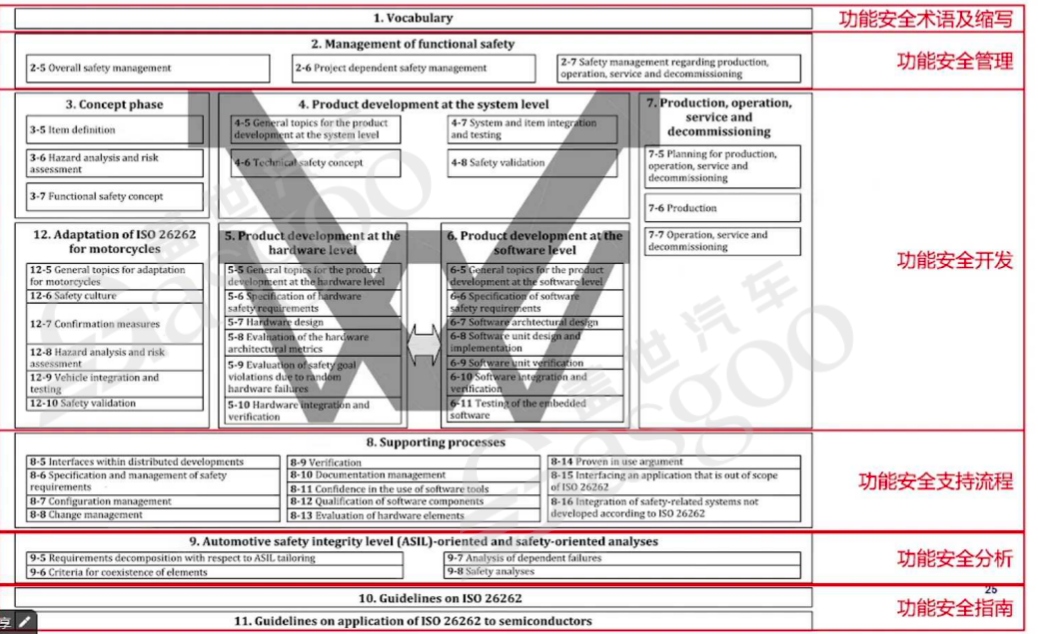

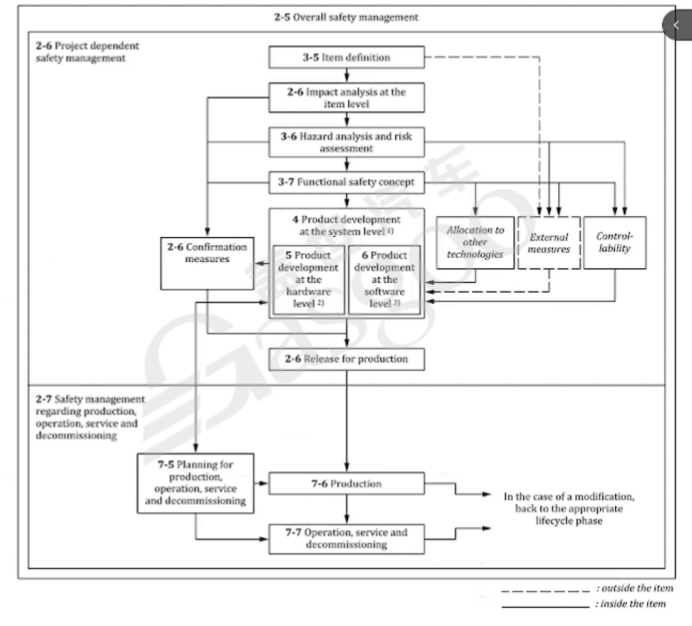

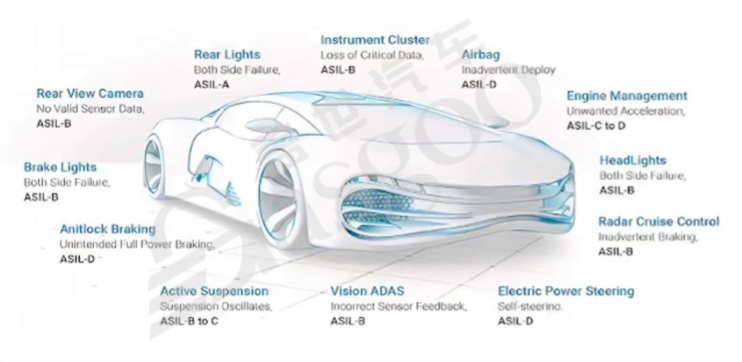

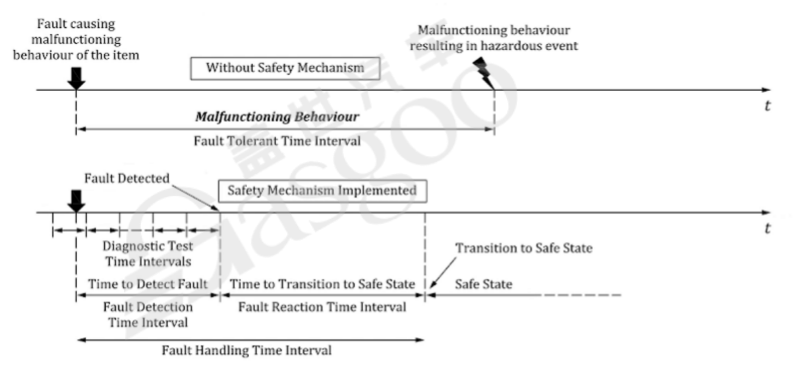

Functional safety is a crucial concept not exclusive to the automotive industry, tracing back to incidents in the 1950s, such as missile explosions during tests and the Apollo 1 fire, which led to the establishment of system engineering and safety management. Key standards in functional safety include IEC 61508, which has significantly influenced the automotive ISO 26262 standard. In response to various safety incidents, including mass recalls by Toyota and Audi due to functional failures, the automotive sector has increasingly prioritized functional safety to mitigate risks associated with unexpected vehicle behaviors. These behaviors can stem from multiple sources, including electronic faults, environmental interferences, driver misuse, and external cyber threats. The evolution of automotive technology necessitates a strong functional safety framework, which has led to the development of various safety standards and protocols, including the GB/T 34590 - 2022 standard in China. Functional safety processes aim to integrate safety measures in the vehicle design and development stages to ensure that risks are controlled to acceptable levels. The ISO 26262 framework categorizes safety integrity levels and emphasizes the importance of early-stage integration of safety requirements to prevent costly late-stage modifications. Overall, as the automotive industry continues to advance, the emphasis on functional safety will play a vital role in ensuring vehicle safety and reliability in an increasingly complex technological landscape.

Understanding Functional Safety in the Automotive Industry

Images

Share this post on: