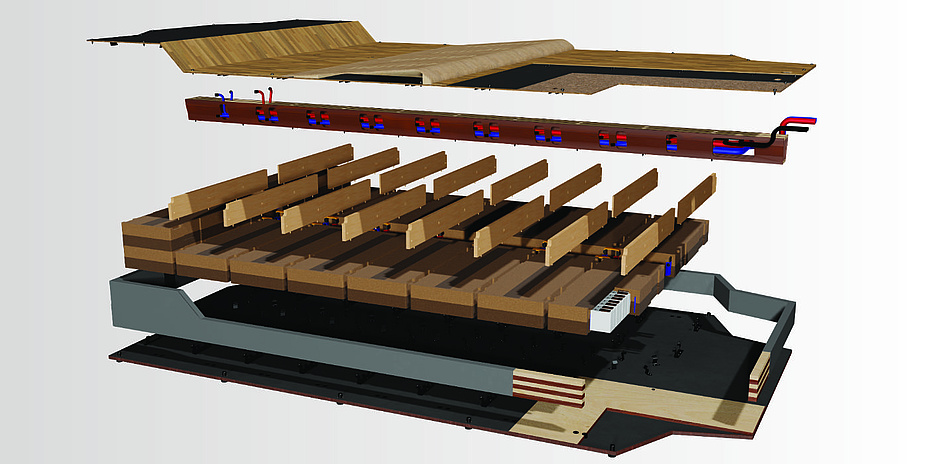

Researchers at TU Graz have developed an eco-friendly battery housing for electric vehicles. Their wood-steel structure has performed exceptionally well in safety experiments and simulation tests, even exceeding market standards in fire resistance tests. While electric vehicles are resource-efficient during operation, the production of batteries and their components still leaves a significant ecological footprint. In the Bio!Lib project, a team led by Florian Feist from the Institute of Vehicle Safety successfully utilized wood and thin steel plates to replace aluminum in the manufacturing of protective housings for electric vehicle batteries. This housing significantly reduces environmental impact and has shown better performance in deformation and fire resistance tests in some cases.

TU Graz Develops Eco-Friendly Electric Vehicle Battery Housing

Share this post on: