Intelligent chassis is a core trend in automotive technology development, involving multi-system coordinated control, AI integration, and drive-by-wire technology to meet the demands for high-precision response and redundant safety in assisted driving. This article discusses the trend of chassis intelligence, functional requirements of assisted driving, challenges of coordinated control, applications of AI algorithms, evolution of hardware platforms, and future architectures.

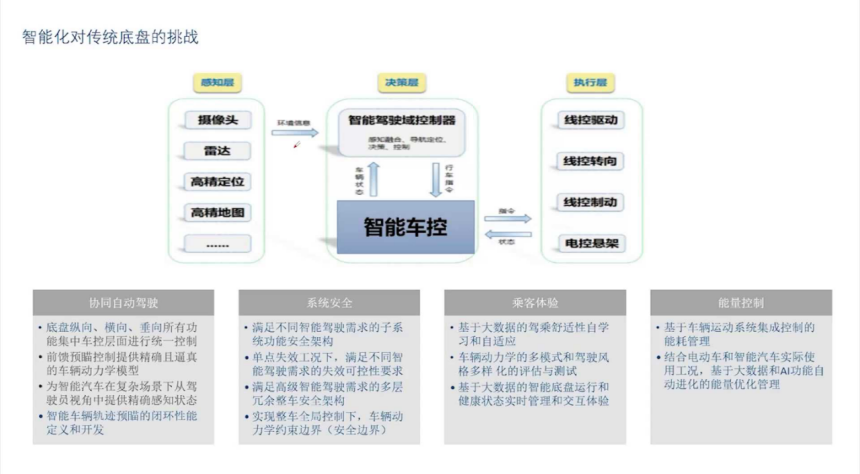

1. Challenges and Introduction of Intelligent Vehicle Control to Traditional Chassis

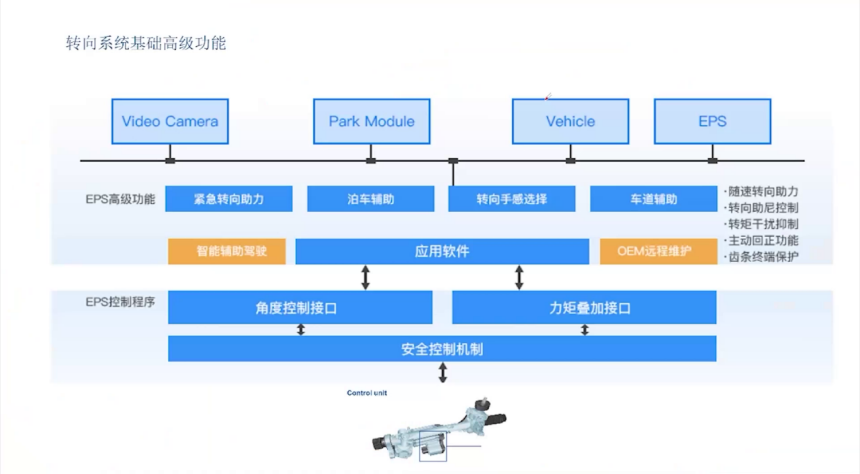

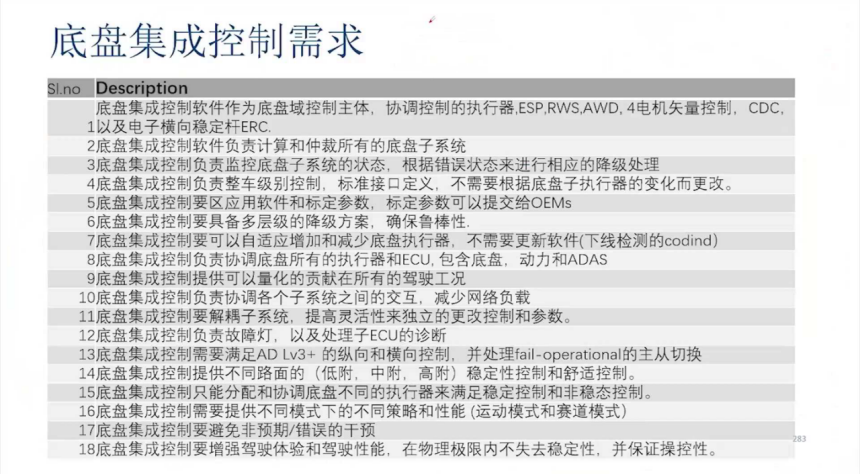

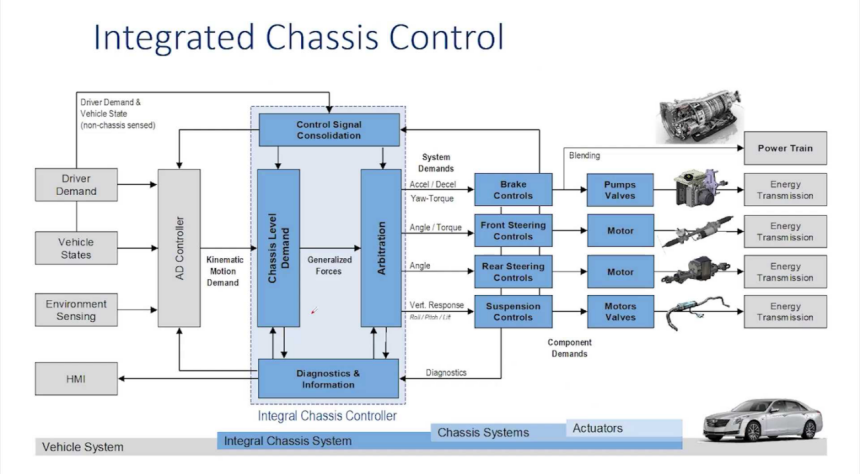

The early design of chassis intelligence relied solely on driver commands for steering and braking control. However, with technological advancements, the number of coordinated tasks has significantly increased, including steering, braking, and differential systems integration, leading to a substantial increase in control system complexity. In response to these increasing control demands, the industry has introduced the concept of intelligent vehicle control, which aims to centrally manage the various functions of the chassis, optimizing the execution effect of feedforward control and avoiding issues such as inadequate steering angles caused by unclear actuator boundaries. Intelligent vehicle control also supports redundancy among chassis systems, enhancing reliability, such as replacing steering with differential steering in case of steering failure. Additionally, it integrates personalized settings and AI algorithms to implement self-learning capabilities to enhance the driving experience.

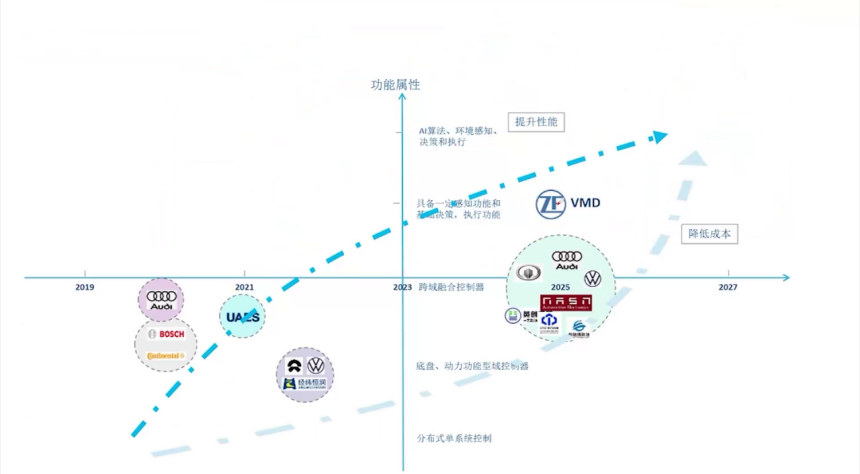

2. Trend of Function Enrichment and Cross-Domain Integration

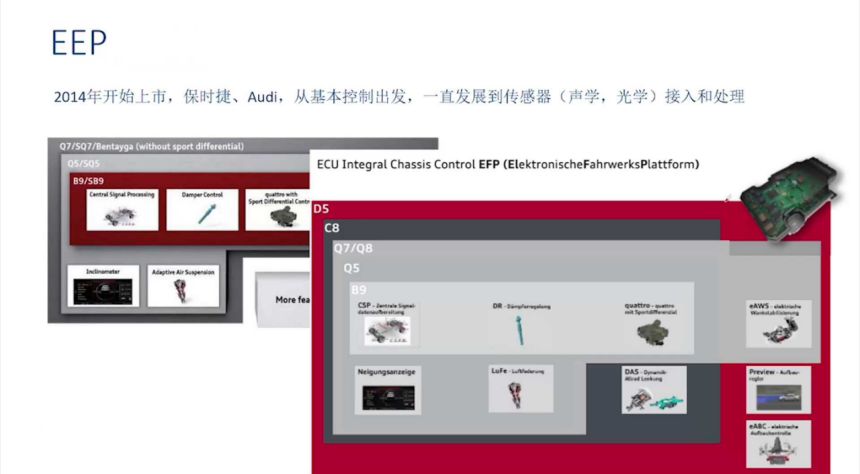

Chassis functions are evolving from single-system control to pre-controller integration, gradually covering more tasks such as perception data processing to adapt to heavy driving demands and increased sensor signals. This reflects the trend of function enrichment: manufacturers are beginning to adopt cross-domain integration solutions like BCM combined with VCU or VDC, indicating that future controllers will need to handle more data types, including acoustic, optical, and electrical sensor information. With the increasing number of chassis sensor systems, pre-controllers must directly process perception data such as road surface scanning and rain detection, employing AI algorithms for edge processing to enhance real-time capabilities.

3. Perception Data Processing and Edge Computing Applications

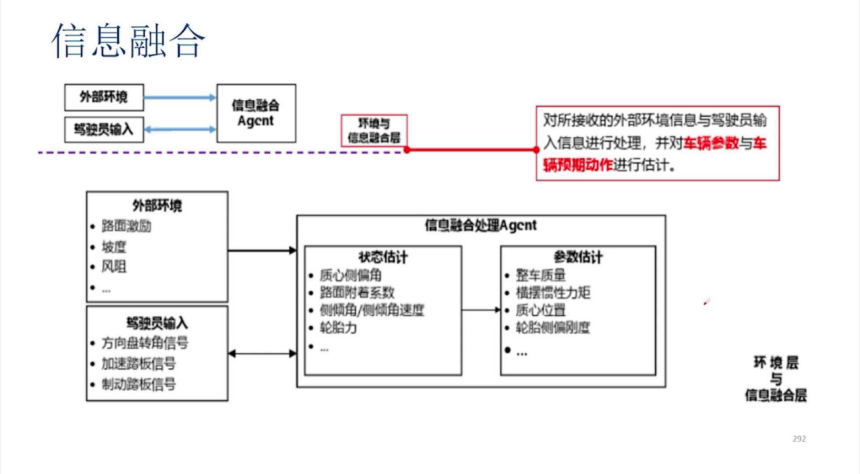

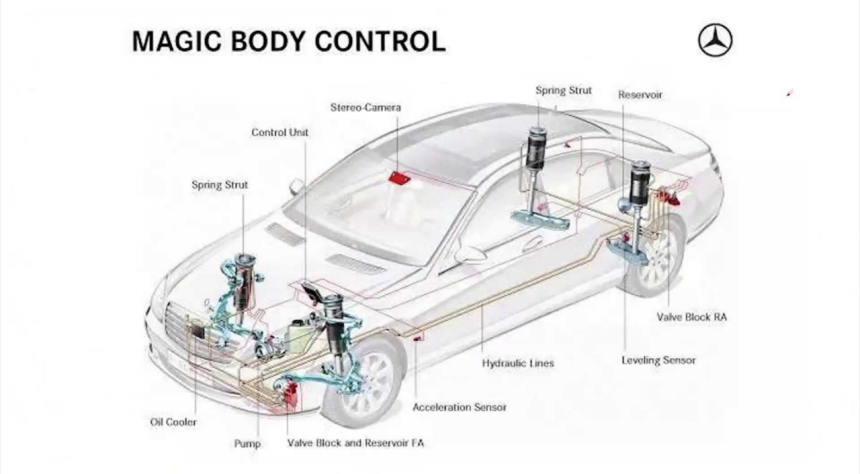

Processing of sensor signals has become a key aspect of chassis intelligence, necessitating clear integration locations (AD or chassis domain controller) to ensure real-time performance. For instance, European teams utilize acoustic sensors to process road surface adhesion coefficients by recognizing tire noise frequency changes under various weather conditions. Optical processing relies on front-facing stereo cameras to identify road surface adhesion coefficients and water conditions. With the increasing demand for sound and optical signals, existing MCUs may be insufficient, and future high-end MCUs will need to support AI algorithms and deep learning for parallel processing. Chassis pre-controllers can directly handle environmental information (like slopes and curves), reducing AD processing delays, which is crucial for real-time control of CDC shock absorbers and steering systems.

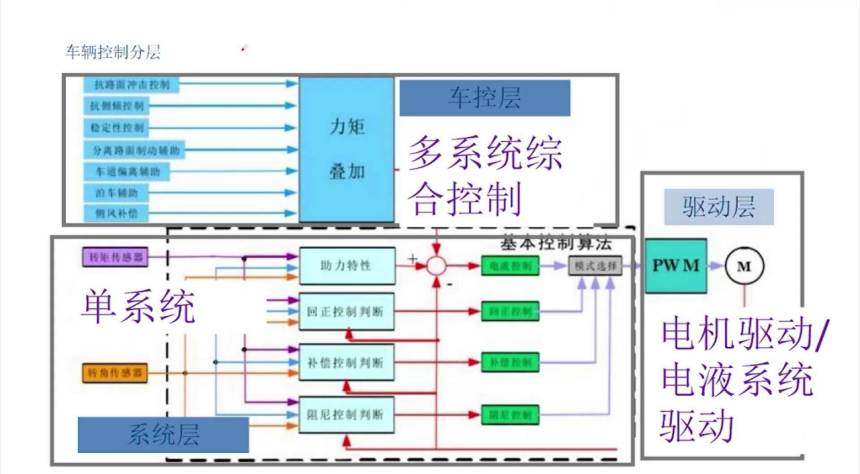

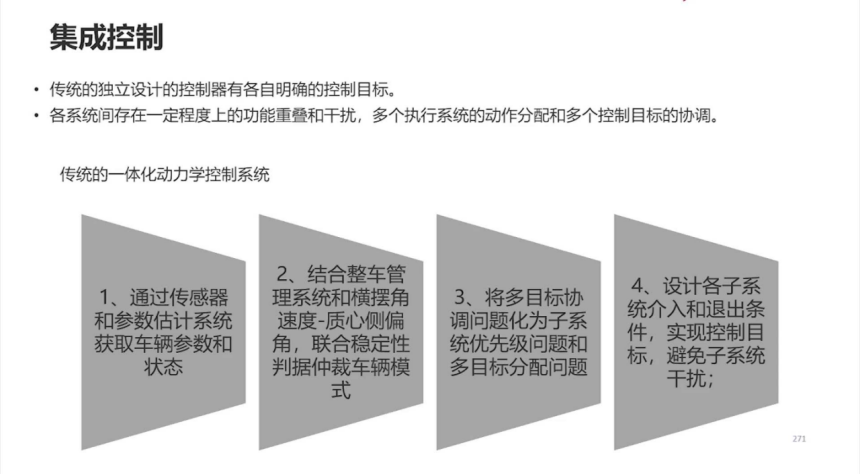

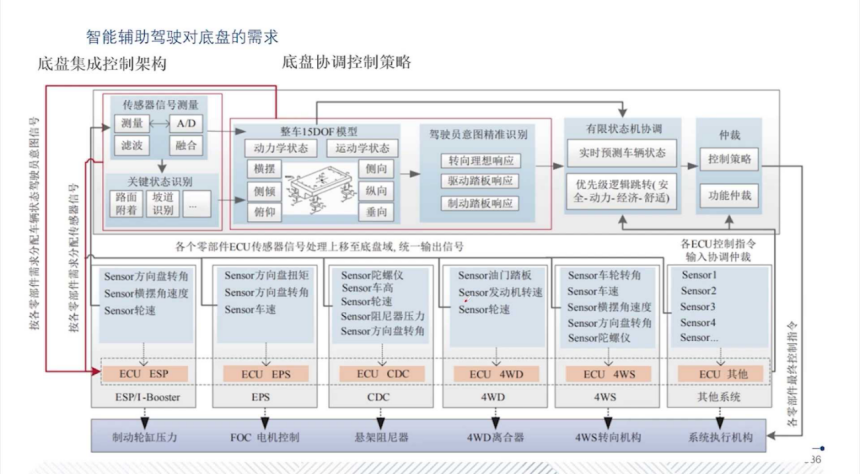

4. Requirements and Practical Challenges of Coordinated Control

Coordinated control faces inter-system conflict issues, as subsystems (like EPS steering) possess independent safety margins and overshoot, leading to inconsistent signal execution or non-responsiveness under specific conditions. Traditional controllers must first estimate and measure vehicle parameters before determining stability criteria through arbitration mechanisms for multi-objective coordination. During design, it is essential to clarify each system's response timing, degree, and execution amount, and to set intervention exit conditions to avoid interference. While traditional integrated control is feasible with fewer systems (2-3 subsystems), it becomes ineffective with the increase in complex systems like CDC, CAS, and lateral stability bars. Real-world cases show that when domestic manufacturers increase sports car configurations, performance improvements are not significant due to control difficulties that force them to adopt conservative segmented strategies, resulting in cornering behavior similar to basic differentials.

5. Model Predictive Control and AI Algorithm Applications

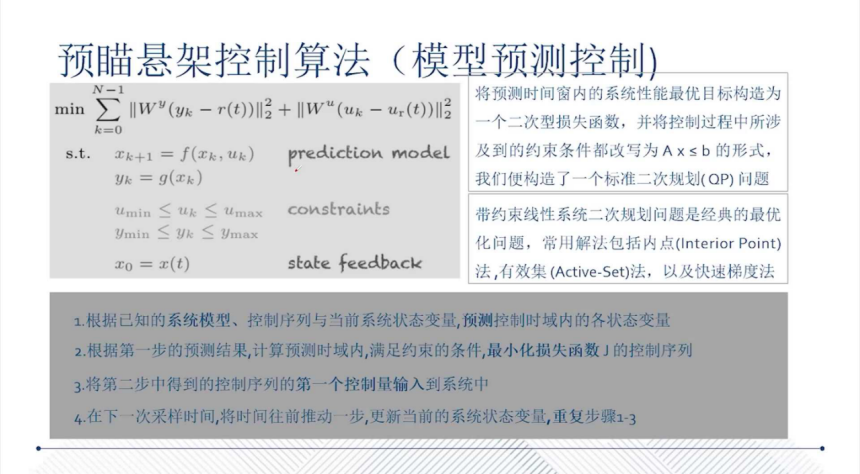

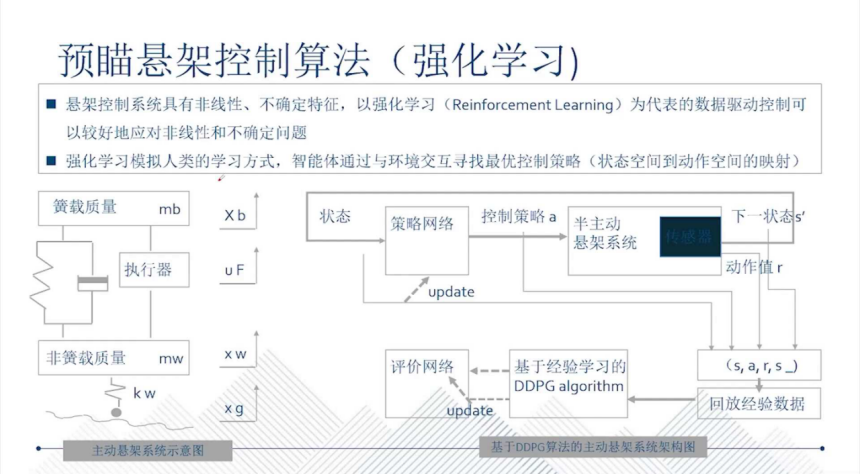

Model Predictive Control (MPC) is gradually replacing traditional lookup-table methods, enhancing adaptability through online rolling optimization to handle complex road constraints. For example, pre-sighted suspension control utilizes cameras to identify road undulations 15 meters ahead, adjusting shock absorber parameters (CDC response of 20-30 milliseconds, and for magnetorheological dampers, 3-5 milliseconds) to optimize ride comfort. Reinforcement learning trains data (like measuring vibration acceleration under CDC electromagnetic valve current) to optimize reward factors (such as body posture coefficients). AI applications, such as lateral stability control, require only sensor data and reference model input without detailed physical models but necessitate extensive cloud-based data learning (as vehicle-side computing power is insufficient).

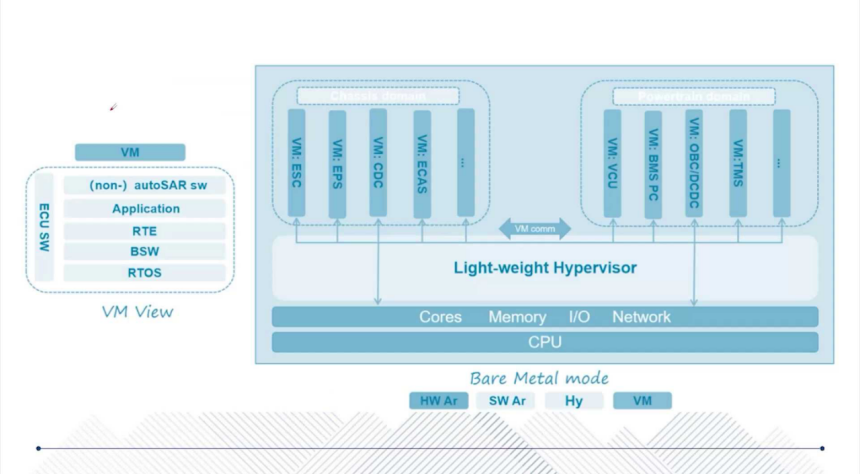

6. Evolution of Chips and Hardware Platforms

Chip performance is crucial for algorithm implementation. Current mainstream options like TC397 are high-end but have shortcomings: they lack virtualization isolation islands, and their network capabilities are weak (supporting only 100 Mbps Ethernet), suitable for single-node or three-node systems. Future requirements are diverse, and chassis systems may not even need TC397-level chips; TC275 (200MHz triple-core) meets most needs. Domestic chips, like Xingchi (formerly NXP team), have launched a triple-core 600MHz product nearing SOC level, supporting virtualization and data routing engines. Manufacturers are exploring platform deployment, such as lightweight Apple system integration into chassis nodes for flexible expansion (like the TC497 case). Hardware design must consider redundancy (dual chips, dual power supplies), while actuator endpoints like six-phase motors enhance reliability. Regional solutions separate the brain from actuators, optimizing power consumption and communication efficiency.

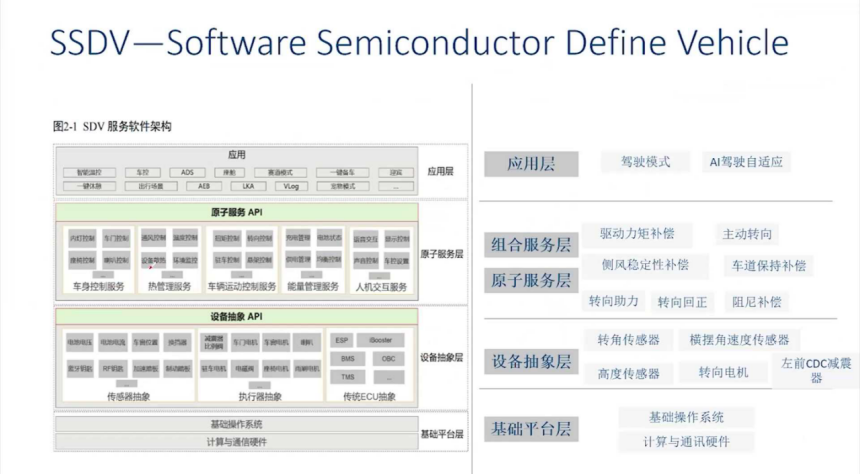

7. SOA Architecture and SDV Development

Service-Oriented Architecture (SOA) improves the design of multifunction controllers, addressing the bottlenecks of traditional CAN network communication. The SDV (Software-Defined Vehicle) association, led by Huawei, promotes standardization by abstracting device layers through atomic services (like invoking braking or steering services), avoiding confidentiality issues with DBC files. The application layer combines service management of hardware without needing to focus on specific forms; vehicle control systems manage steering, braking, suspension, driving, and energy management (like CDC system thermal management). By leveraging AD technology, innovations in control algorithms and SOV architectures are realized, but challenges in communication methods (like high-current actuators requiring specific communications) must be addressed.

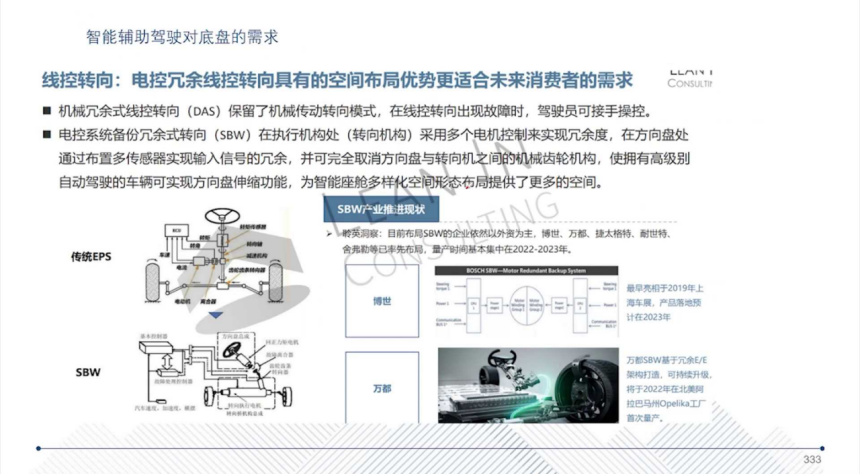

8. Drive-by-Wire Chassis and Intelligent Assisted Driving Needs

Drive-by-wire chassis are a prerequisite for L4 assisted driving, requiring redundancy technologies (like mutual backup for braking and steering) and longitudinal and lateral coordination control. For example, ESC can apply different braking forces on left and right wheels to achieve steering redundancy; system-level redundancy is planned overall by manufacturers to meet functional safety. Electric power steering prevents grabbing of the steering wheel while avoiding legal risks (such as accidents caused by malicious actions from passengers). The execution endpoint has sensing functionality, resembling human touch (like tire sensors providing road coefficient feedback); the more sensory input, the more accurate the AI learning results. Musk's philosophy emphasizes the vehicle's learning capability rather than preset rules; the chassis domain controller coordinates actuators (driving, braking, steering) to achieve a modular assisted driving architecture. Status recognition (slope, adhesion coefficient) is the greatest challenge, as existing algorithms largely rely on feedback rather than feedforward; overall vehicle models need optimization under high acceleration dynamics, and estimation methods require further research.

Chassis intelligence is profoundly reconstructing the automotive control system, achieving coordination among steering, braking, and differential systems through the intelligent vehicle control hub, breaking through the limitations of traditional ‘black box’ isolated control. This process, driven by AI algorithms to enhance self-learning capabilities, model predictive control to optimize execution accuracy, and distributed architectures to reduce computing costs, has made breakthroughs in redundant safety, perception fusion, and hardware evolution dimensions. However, complex system coordination still faces challenges such as delayed state recognition, multi-objective optimization weight distribution, and high-precision model construction, necessitating the combination of virtual calibration and digital twin technologies to overcome calibration bottlenecks. In the future, as SOA service-oriented architectures become widespread and drive-by-wire chassis standardization progresses, vehicles will achieve a closed-loop upgrade of 'perception-decision-execution', providing a dynamic control base for L4-level assisted driving with millisecond-level response, ultimately achieving an integrated advanced assisted driving ecosystem of 'human-vehicle-road-cloud'.

The Trend of Intelligent Chassis in Automotive Technology Development

Images

Share this post on: