CTC (Cell to Chassis) technology is a core innovation in battery integration for electric vehicles, reshaping the landscape of automotive manufacturing. This article delves into the application of CTC technology, exploring its definition, comparisons of different manufacturers' solutions, structural design, manufacturing challenges, and real-world cases, highlighting its key role in enhancing energy density, reducing costs, and improving production efficiency.

1. Overview and Definition of CTC Technology

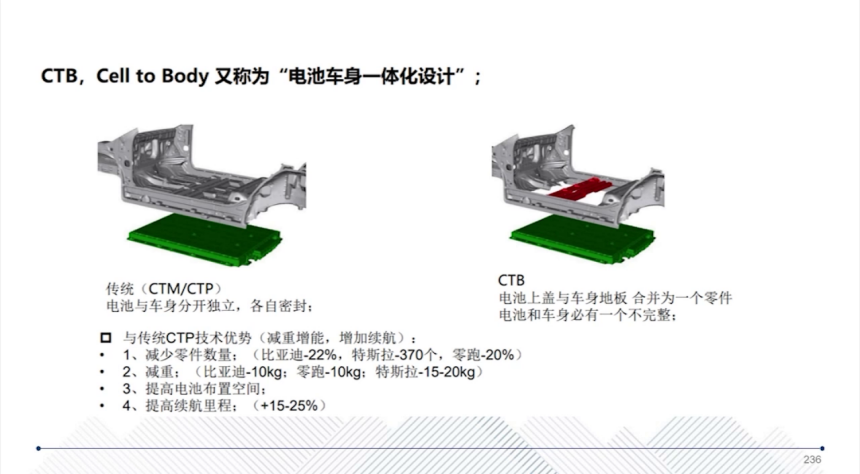

CTC technology involves two main methods: Cell to Chassis (CTC) and Cell to Body (CTB). The C2C method emphasizes the direct integration of battery modules into an independent chassis structure, while CTB embeds battery cells directly into the vehicle's body floor, eliminating the need for a separate chassis. Traditional body designs lack a separate chassis, which means batteries are usually installed within the body, aligning more closely with the CTB concept. For example, Tesla employs the CTB approach by integrating battery cells directly into the body floor, while Canoo and a few other companies utilize the C2C method to incorporate modules into the complete chassis. Currently, only a handful of companies, such as Canoo and Rivian, possess independent chassis supporting CTC solutions, while others, including Tesla, rely mainly on CTB strategies due to body design constraints. This technological difference arises from the presence or absence of chassis structure, directly affecting the flexibility and efficiency of battery integration.

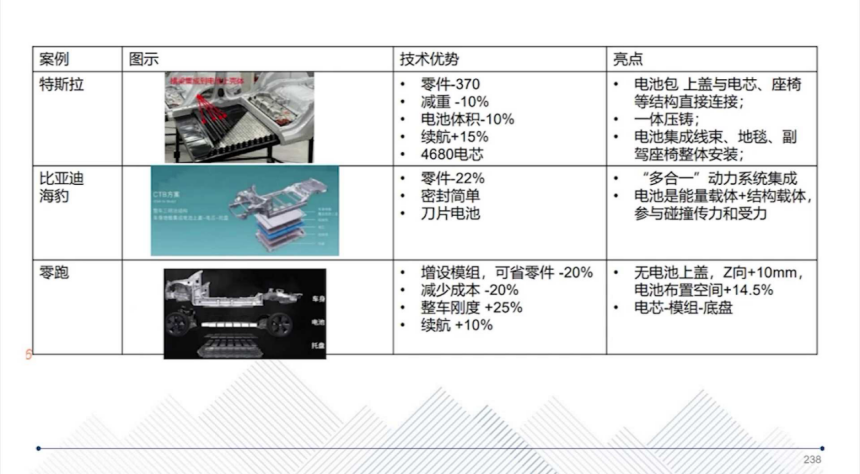

2. Comparison of Different Manufacturers' CTC Solutions

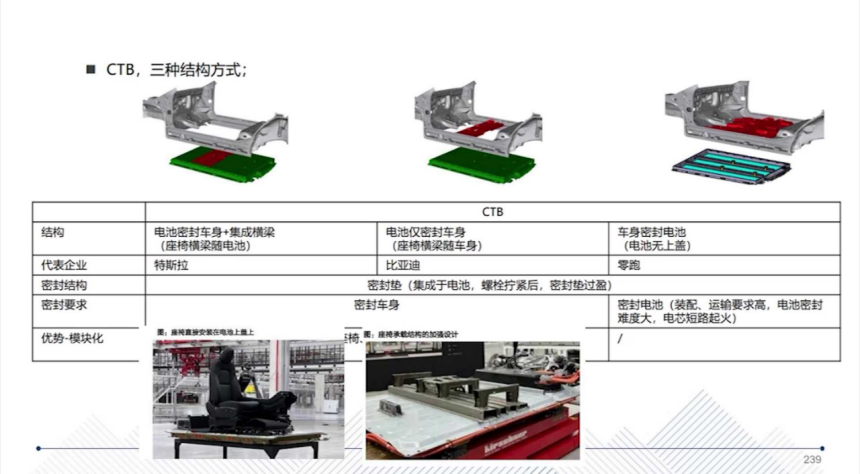

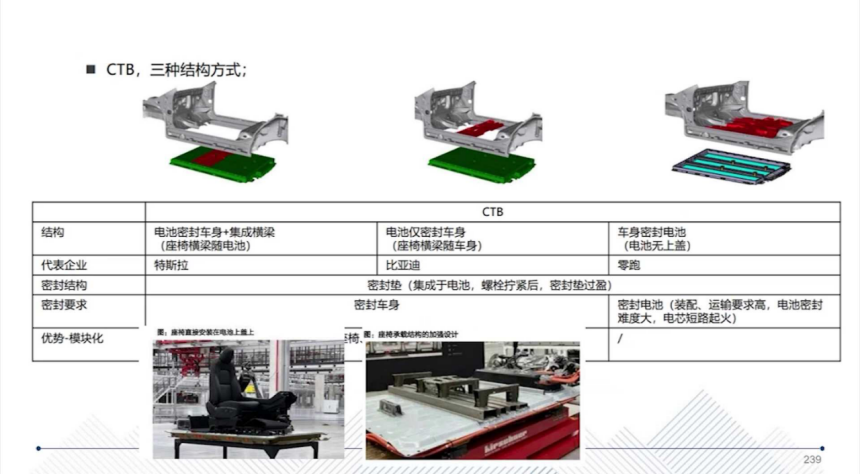

Major electric vehicle manufacturers adopt varying solutions for CTC technology. Tesla's CTB technology integrates the battery cover plate with the cells and seat structure, significantly reducing the number of parts (reportedly by 370) and lowering the center of gravity to enhance handling performance. BYD's blade battery uses a stacked design particularly suitable for CTB integration, simplifying the sealing process while providing structural rigidity that distributes pressure during lateral collisions and torsional loads. Leapmotor's CTC solution aggressively eliminates the battery cover plate, directly merging the cover with the vehicle's floor, saving about 10mm of space and claiming a 25% increase in rigidity while reducing costs by 20%. In contrast, Canoo's CTC solution fully integrates the module within the frame, allowing the vehicle body and battery pack to operate independently, facilitating modular customization. Each of these solutions has its strengths and weaknesses: Tesla's and BYD's approaches emphasize sealing and structural strength, while Leapmotor's solution is more efficient in space utilization but faces significant sealing challenges, particularly during transportation where factory debris could pose a short-circuit risk.

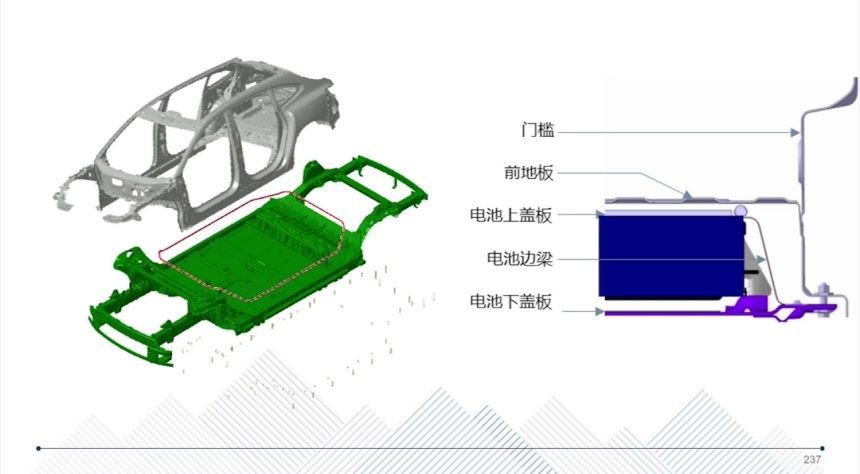

3. CTC Structural Design and Key Components

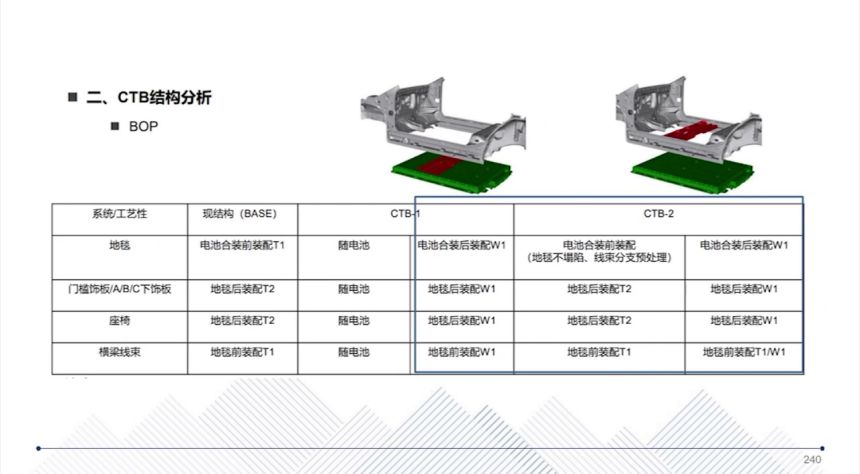

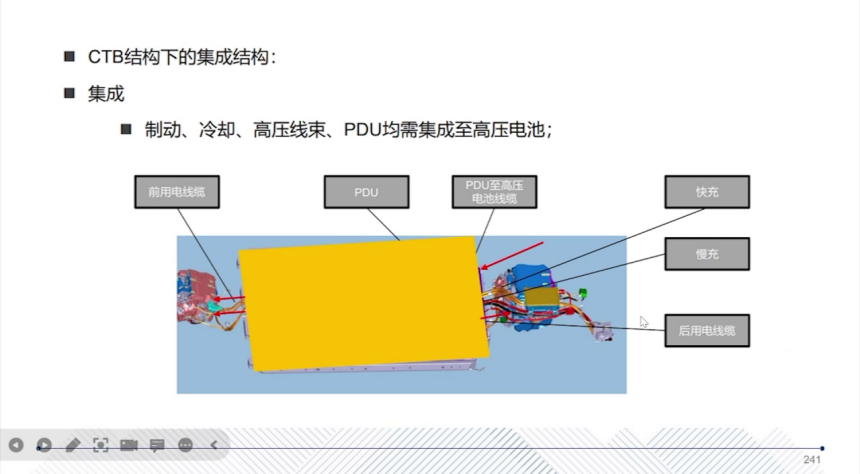

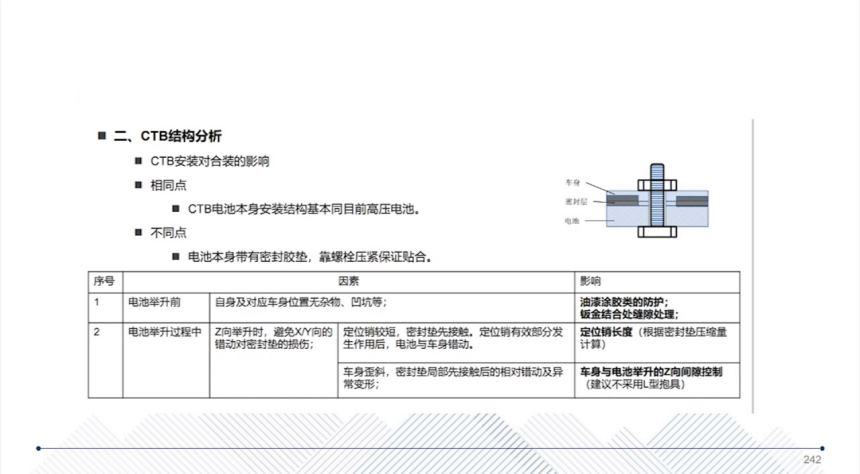

The key to CTC structure lies in the design of components such as the threshold beam, front bottom plate, and battery cover plate, where the integration of these parts directly impacts structural stability and safety. For instance, combining the front panel and battery cover plate can reduce the number of components, lowering the probability of failures, but it increases the risk of sealing failures, especially when battery cells are integrated directly into the body floor, necessitating consideration of seat connection devices and human loads. Under CTB structure, assembly sequences for components like carpets, threshold trims, and seats need adjustments, such as installing the carpet after the battery is assembled (W1 stage), leading to significant process differences. The integration of cooling systems is particularly critical; PDU, high-voltage harnesses, and cooling pipes must be embedded within the battery compartment, complicating process layout. For example, a water-cooled high-voltage system requires efficient layout of inlet and outlet ports, while air-cooled systems are less commonly adopted despite their advantages. Sealing challenges are amplified during mass production, where unpolished or burr-ridden body sections may result in connection point failures, and even a defect rate of 1‰ is unacceptable, necessitating collaboration with the body department to optimize manufacturing processes.

4. Manufacturing Processes and Assembly Challenges

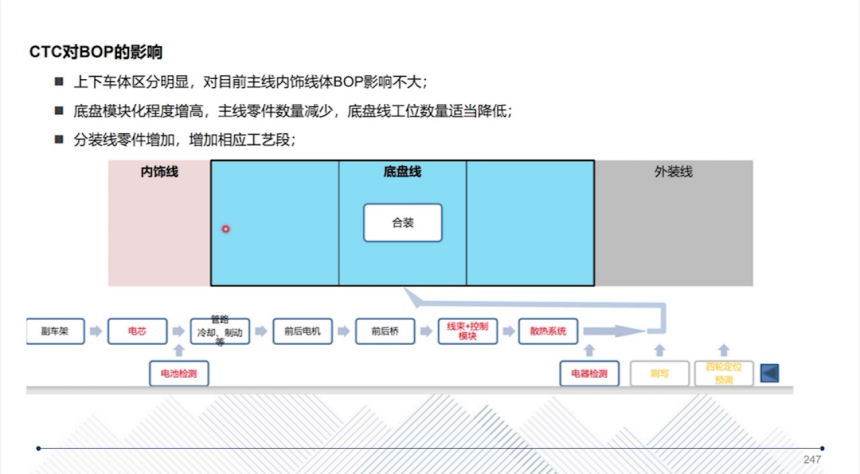

CTC assembly requires high-precision positioning and support systems, such as using positioning holes with a diameter of at least 20mm and multi-hole positioning strategies to overcome tolerance issues arising from frame length. The assembly sequence also needs optimization, such as fixing the middle battery compartment section first, then installing the front peak, and finally addressing the rear lateral connection points to ensure even load distribution and avoid NVH noise and component failures. In mass production, tolerance control is a significant challenge, needing to be maintained within ±2mm; otherwise, frequent manual adjustments could limit output (as Rivian's production capacity is constrained by tolerance issues). The CTC disassembly line requires new areas for battery packaging, routine disassembly, and inspection, where battery disassembly demands a clean sealed environment and includes charge/discharge testing, resulting in high space requirements and investment costs; adhesive application processes necessitate drying areas for battery packs, increasing the size of stacking areas and labor hours. To enhance efficiency, automation solutions could be explored, such as grouped assembly of blade battery blocks or using self-driving vehicles for transport.

5. Battery Technology and Volume Utilization Optimization

The choice of battery directly impacts CTC performance. Tesla utilizes cylindrical cells with a winding technique (such as the 4680 large-cell), achieving a volume utilization rate of approximately 28.9%, while Canoo employs LG's 46 parallel and 96 series configuration, achieving a volume utilization rate of 32.5%, allowing for more cells to fit in the same space. BYD's blade battery achieves a volume utilization rate of 62.3% through stacked technology, revolutionarily simplifying the construction of the 800V platform, requiring only 124 series connections without complex soldering. Lithium iron phosphate batteries can be arranged within limited spaces for up to 120 degrees of charge, but long blade batteries are restricted in corner areas and need smaller blade groups for assembly. High energy-density batteries (like blade batteries) facilitate the integration of controllers into the cockpit, but EMC issues need resolution. Competitive analysis shows significant differences among brands in voltage platforms, series/parallel structures, and energy densities, such as BYD's Haipao 54kWh battery employing CTP technology with the highest volume utilization.

6. Manufacturing Planning and Implementation Strategies

Implementing CTC requires adjustments to the production lines at OEMs, such as adding a disassembly workshop next to the final assembly line for battery cell assembly, cooling pipe installation, and motor fitting, subsequently integrating these components into the vehicle body as a complete unit to minimize impact on existing production lines. However, decision-making faces challenges: OEMs must weigh the risks of building their own production lines against supplier collaboration models, with internal opinions often divided—some are concerned about the complexity of changes, while others believe that failing to innovate will lead to losses. A gradual strategy is recommended, beginning with small-batch C2C validation of sealing and layout technologies, then evolving to CTB applications. Path dependence hinders innovation, as OEMs tend to adopt follow-up strategies rather than proactive changes. Ultimately, the core of CTC lies in simplifying structures, enhancing space utilization, and reducing costs, while balancing sealing, safety, and mass feasibility.

7. Conclusion and Industry Outlook

CTC technology promotes structural optimization in electric vehicles through high integration, but widespread application must overcome manufacturing bottlenecks such as tolerance control, sealing reliability, and disassembly line investments. The industry should draw lessons from successful cases (such as Tesla's automated assembly) and focus on battery technology innovations (like the high volume utilization of blade batteries). In the future, CTC is expected to achieve standardized skateboard chassis, but it requires cross-departmental collaboration and process optimization to enhance daily output and competitiveness.

CTC Technology: Revolutionizing Electric Vehicle Manufacturing

Images

Share this post on: