With the acceleration of automotive intelligence, the requirements for data transmission in advanced driver-assistance systems (ADAS) have increased. High-speed and high-frequency connection solutions, as the core of the automobile's 'nervous system,' directly impact the quality of signal acquisition from perception devices such as cameras and LiDAR, data processing in decision-making controllers, and the transmission of execution commands for braking and steering, becoming the key foundation for ensuring stable operation of ADAS. On July 22, 2025, Song Tang, Sales Director of TE Connectivity's Automotive Division, stated at the 8th Smart Driving Assistance Conference: 'The data signal transmission of ADAS requires solutions that are good, abundant, and efficient. TE Connectivity ensures stable signal transmission through its full-link high-speed and high-frequency connection technology.'

In the field of ADAS, the reliability of connectors directly affects system safety. TE Connectivity has established a comprehensive quality closed-loop system, maintaining a product defect rate of less than 0.2 PPM in 2024, with 100% compliance with quality standards for newly developed products. For complex road conditions, the connection solutions offer protection performance exceeding industry standards: mechanical impact testing shows transient shock resistance of over 30+m/s², meeting high vibration resistance requirements for vehicular electrical equipment. Electromagnetic shielding efficiency is above the market average by more than 10%, and combined with high-frequency and EMC cooperative analysis capabilities, it ensures triple protection for vibration resistance, shielding, and smoothness, guaranteeing stable signal transmission in extreme temperature changes, vibrations, and electromagnetic interference environments. The solution significantly shortens the verification cycle for harsh environments through thermal simulation analysis and customized 3D-printed rubber soft films, laying a reliable data transmission foundation for ADAS.

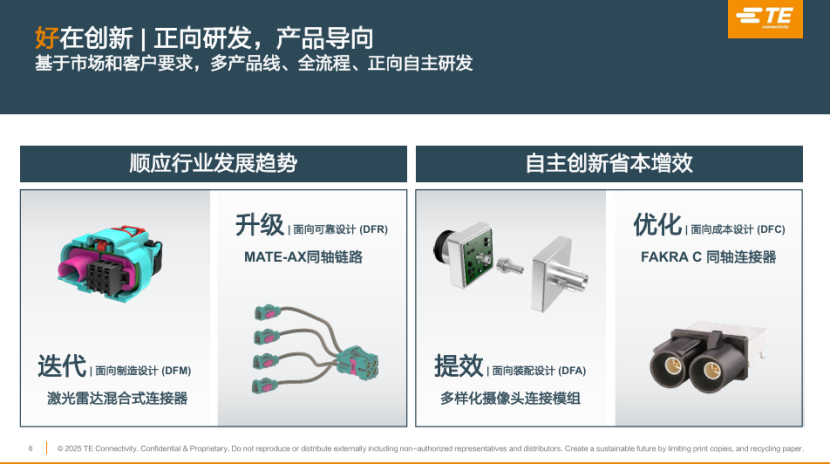

TE Connectivity has constructed a forward research and development system that collaborates across multiple product lines to develop innovative solutions based on cutting-edge market demands. Four to five years ago, the company partnered with leading LiDAR manufacturers to develop the industry's first hybrid connector, addressing the market's lack of compatible solutions and filling a technological gap. In response to the demand for centralized electronic architecture, TE launched the MATE-AX miniaturized coaxial connector, reducing equipment ports by 40% through a 4x7 integrated layout, optimizing assembly efficiency. The new generation of camera modules features an integrated metal back cover design, supporting 8M/12M (4K level) high-resolution imaging while optimizing heat dissipation structures to tackle environmental temperature rise challenges. Utilizing agile development with 3D-printed rubber soft films, coupled with system-level vibration analysis, EMC simulation, and thermal simulation verification capabilities, it significantly shortens the sample cycle for new solutions, ensuring rapid design iteration. This system spans the entire process from market trend analysis and product definition to verification, continuously promoting upgrades in connection technology, driving cost optimization and performance enhancement to provide reliable foundational support for ADAS.

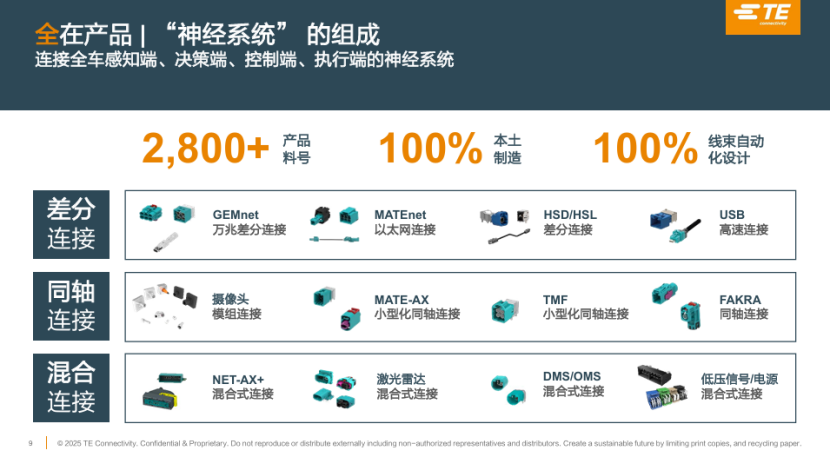

The connection system has achieved full-link coverage from perception to execution, including over 2,800 standardized part numbers. At the perception layer, specialized connection solutions for LiDAR and high-definition cameras ensure stable transmission of high-precision environmental perception signals. The decision layer is compatible with ADAS domain controllers and main/cockpit domain controllers, supporting multi-source data processing needs. The execution layer covers braking, suspension, steering, and drive systems, ensuring precise command delivery. The human-machine interaction end supports display devices, head-up displays, and external device ports, optimizing user interaction experience. All products are 100% domestically manufactured, with 100% automated design of wiring harnesses. Through innovative differential connections, coaxial connections, and hybrid connection technologies, the challenges of multi-system signal matching are resolved, constructing a complete neural signal transmission network from environmental perception to data processing and mechanical execution, providing a high-reliability, low-latency data pathway foundation for ADAS.

To meet the industry's demand for cost reduction and efficiency improvement, TE Connectivity has created a collaborative development model of 'chip-material-cable': it has built a system-level verification platform with leading domestic ADAS chip manufacturers to ensure that connection solutions upgrade in sync with chip computing power. Collaborating with material suppliers, it has developed specialized plastic particles and copper materials, achieving cost reductions in wiring harness systems through innovative material collaboration. By leveraging digital technologies like thermal simulation analysis to proactively identify extreme working condition failure risks and combining EMC simulation analysis and customized 3D-printed rubber soft film technologies, TE has dramatically shortened verification cycles. Relying on its engineering center in Suzhou, which employs 1,100 people and seven factories, the company has established an industrial ecosystem capable of delivering 10 million sets of high-frequency and high-speed connectors and wiring harness systems annually, forming a comprehensive collaborative system that covers research and development verification, material innovation, and mass manufacturing.

Looking ahead, with the surge in the number of sensors and the centralization of electronic architecture, multi-system signal fusion will become a key technical challenge. TE Connectivity has proactively laid out hybrid connection technology solutions to address compatibility challenges between differential, coaxial, and low-voltage products, focusing on breaking through technical bottlenecks in electromagnetic compatibility for high-density integration solutions, utilizing digital tools like EMC simulation analysis to optimize designs. Simultaneously, it deepens collaborations with chip manufacturers to promote the establishment of industry-level connection standard protocols, constructing a more open industrial cooperation ecosystem for resource sharing and technological co-creation. This strategy, supported by a system-level verification platform and collaborative material innovation, ensures that connection solutions upgrade in sync with chip computing power, providing reliable support for future ADAS.

TE Connectivity's Innovative Connection Solutions Empower Smart Driving

Images

Share this post on: