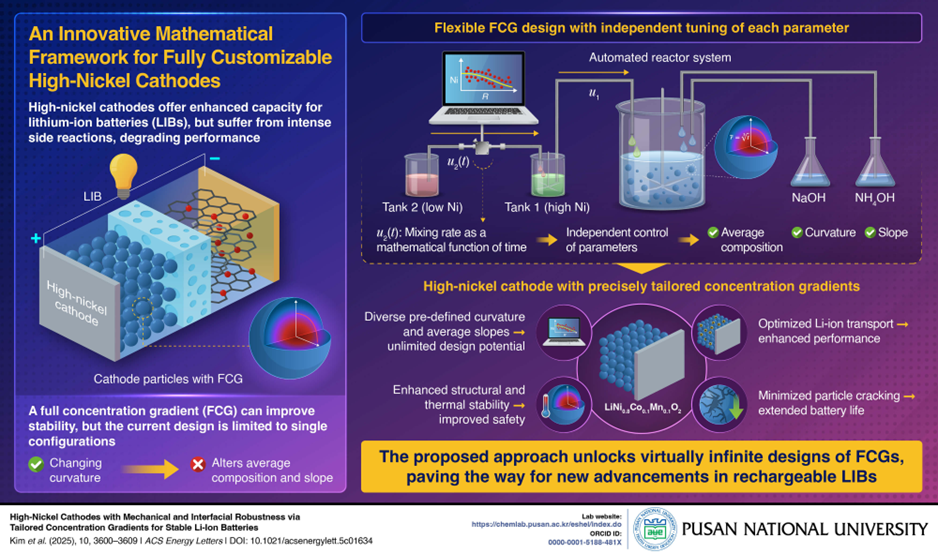

As the global renewable energy and electric vehicle industries accelerate, the demand for lithium-ion batteries (LIB) is rapidly increasing. The performance and stability of LIBs largely depend on the cathode materials, which account for 40% to 45% of the total battery cost. In cutting-edge battery technology, high-nickel cathode materials stand out due to their ultra-high energy density and significant cost-effectiveness. However, the increase in nickel content also intensifies side reactions, severely compromising interface robustness and mechanical integrity, which are factors limiting their widespread application. A promising solution is the use of full concentration gradient (FCG) or core-shell structural designs. In such structures, the nickel concentration gradually decreases from the core to the surface of each cathode particle, replaced at the surface by more stable elements like cobalt and manganese. This gradient enhances surface stability and mechanical strength. Unfortunately, current preparation methods offer limited tunability. Once the average composition is determined, the slope and curvature of the gradient are constrained, restricting the design flexibility of FCG cathodes.

Growing Demand for Lithium-Ion Batteries Driven by Renewable Energy and EV Industry

Share this post on: