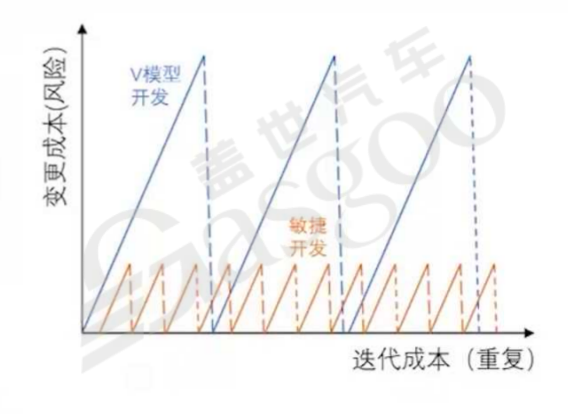

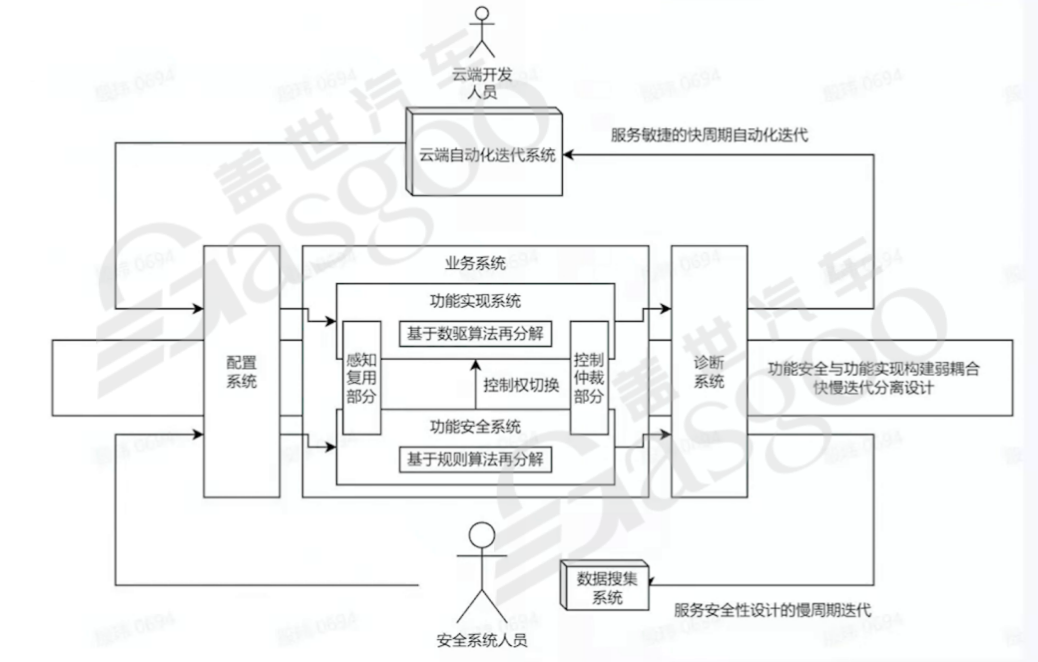

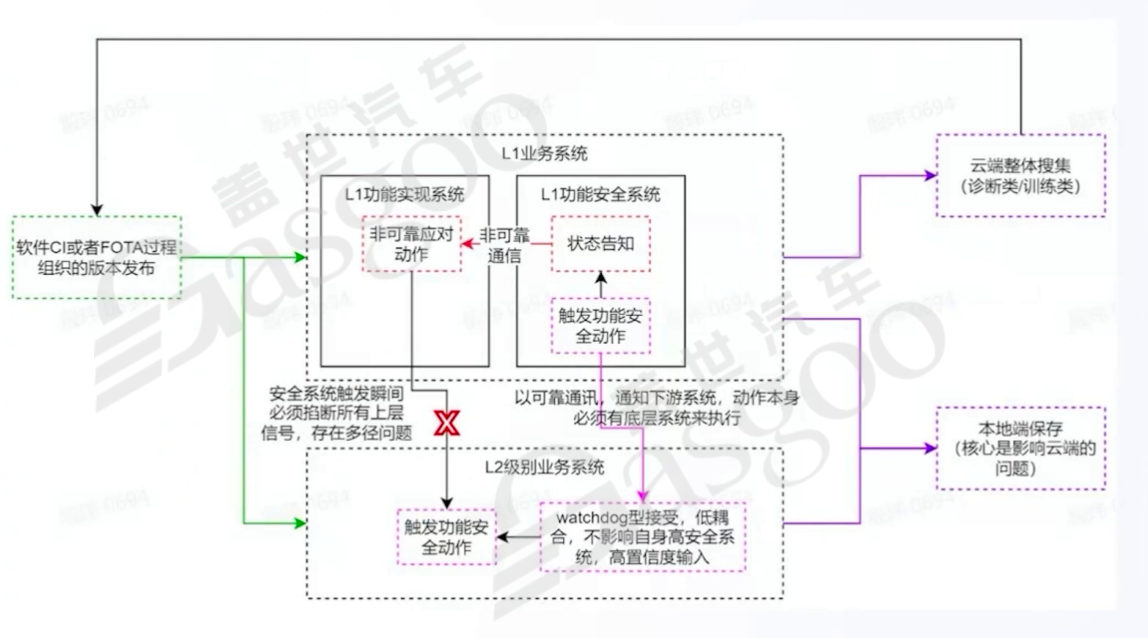

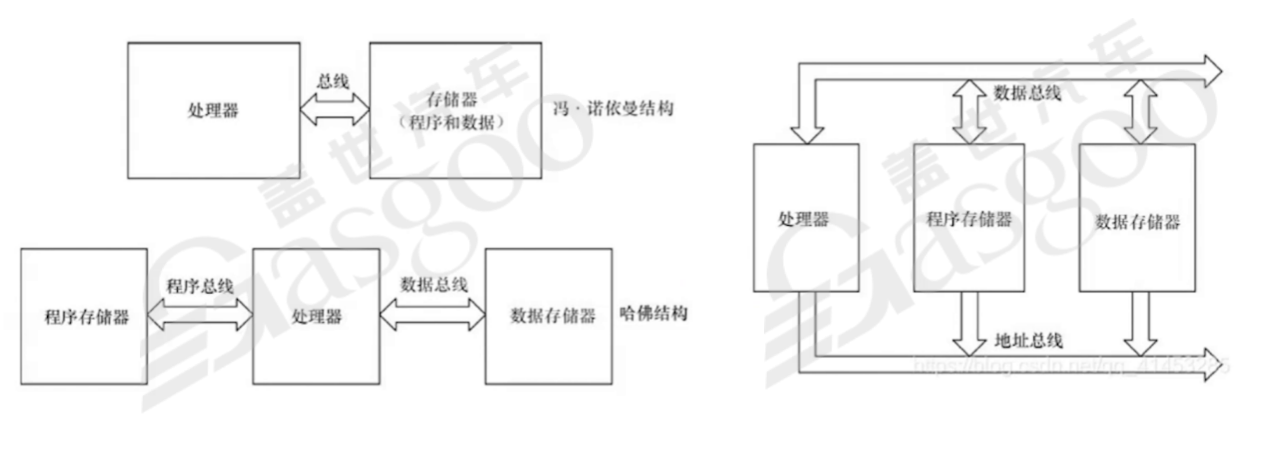

The automotive industry is undergoing a transformation from traditional mechanical products to intelligent hardware-software integrated products, highlighting the collision between vehicle development thinking and internet development thinking. Although these two approaches appear to be oppositional, they both center around risk avoidance, albeit through very different paths. Vehicle development thinking focuses on hardware as the core carrier, where the physical properties of hardware result in high change costs—every modification from design adjustments to production line alterations requires significant investment and time. Consequently, the vehicle development process typically involves only 3-4 iterations and heavily relies on stringent preventive measures to mitigate risks. This development model adheres to the V-model, emphasizes process and documentation systems, advocates for separation of powers and conservative thinking, and aims to serve the long lifespan of hardware. In contrast, internet development thinking prioritizes software, where the virtual nature of software allows for lower change risks but higher iteration frequencies. To accommodate such rapid iterations, internet thinking sets its core goal as reducing the cost of each iteration, adopting an agile development model, focusing on scalability and data pipeline construction, and is driven by unified powers and radical thinking, centering on short-term software update needs. SOA, a product of internet thinking, further compresses iteration costs by breaking down functional modules and minimizing change impacts. Importantly, these two types of thinking are not mutually exclusive. As vehicles are a combination of hardware and software, high-quality development must be supported by solid foundational construction and interdisciplinary talent. Lacking these elements, a blind application of internet thinking may result in uncontrolled risks, while strict adherence to traditional vehicle thinking may lead to a loss of product competitiveness. In terms of development logic and toolchain conflicts, vehicle thinking relies on causal reasoning; any functional safety certification or requirement design must undergo rigorous logical chain verification. This approach ensures reliability but sacrifices agility. Conversely, internet thinking is based on correlation analysis, where network models learn the relationships between elements without delving into intermediate logic as long as the end results meet standards. This approach speeds up iterations but decreases interpretability. The current industry shows a trend of mutual integration, with traditional automakers beginning to relax some documentation requirements to accelerate delivery, while internet companies enhance process construction to improve reliability. However, this integration has not eliminated essential differences. For example, in the simulation software field, tools dominated by automakers emphasize unified industry standards, while internet companies adopt self-built standards to ensure internal coherence, resulting in conflicts during testing due to incompatible formats and protocols. Disparities in toolchains are also pronounced. Automakers focus on standardizing individual links, such as high-precision map interchange standards, but neglect the collaborative automation of adjacent modules in the vehicle-cloud chain. Internet companies, on the other hand, pursue full-chain coherence with unified standards from data collection to model training but refuse to adhere to industry-wide norms. This difference complicates collaboration between MBD (model-driven development) and CBD (code-driven development) engineers, with barriers in operating systems, programming languages, and dependency libraries, increasing cross-team communication costs. The decoupling path between functional safety and feature realization is crucial, where the core principle of system separation dictates that the functional safety system should not participate in the main feature realization, leading to a weak coupling relationship. The primary responsibility of the functional safety system is to control risk, ensuring that vehicles do not experience catastrophic accidents. This type of system is suitable for rule-based algorithms relying on clear logical judgments and must pass strict functional safety certifications, such as ISO 26262, resulting in longer but more stable iteration cycles. On the other hand, the feature realization system focuses on enhancing user experience and can adopt data-driven network models capable of frequent optimizations with lower interpretability requirements but must respond quickly to market demands. For instance, Huawei’s ‘veto power’ mechanism allows the feature realization team to propose innovative solutions while the functional safety team only rejects risky proposals without intervening in the actual implementation, ensuring agile feature iterations while maintaining safety standards. In automotive development, a similar logic is reflected in algorithm planning attempting aggressive paths for experience enhancement while the control system remains conservative, taking over the vehicle immediately upon detecting risks. The challenge of cross-domain collaboration arises due to the significant 'language barrier' stemming from the differing development mindsets of vehicle and internet development. MBD engineers and CBD engineers struggle to cooperate due to varying toolchains and methodologies, while conflicts often occur between functional safety and feature realization teams due to differing priority goals. Solutions include establishing cross-domain talent training systems and standardized communication mechanisms. For example, a car company established an 'architecture translator' role to relay requirements between hardware and software teams, converting functional safety metrics into chip computing needs and algorithm iteration requirements into middleware specifications, effectively lowering communication costs and improving the matching of hardware change cycles with software iteration frequencies by 40%. The future trends balancing functional iteration and functional safety are likely to see three major convergence trends: methodological integration, where traditional automakers incorporate more data-driven approaches to optimize functional safety strategies, and internet companies strengthen process construction; technical architecture integration, with a move towards 'cloud-edge-end' collaboration; and talent system integration, where interdisciplinary talents who understand both automotive safety standards and machine learning algorithms become core competencies. In conclusion, the relationship between functional iteration and functional safety is interdependent rather than irreconcilable. Through system decoupling, architectural optimization, and ecological collaboration, the automotive industry can achieve a development model that is both fast and stable, promoting the deployment of advanced driver assistance systems in large scales.

Core Differences Between Vehicle Development Thinking and Internet Development Thinking

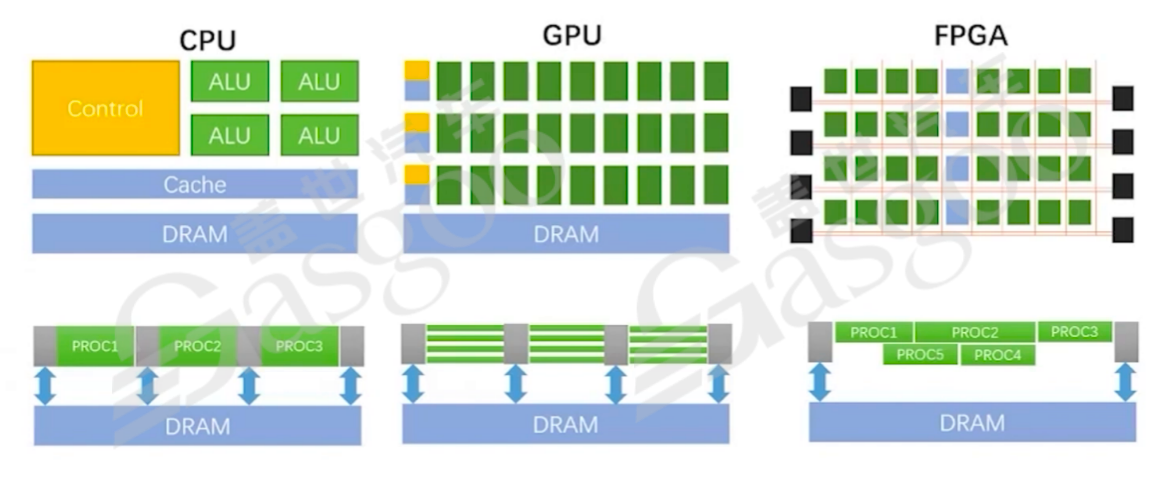

Images

Share this post on: