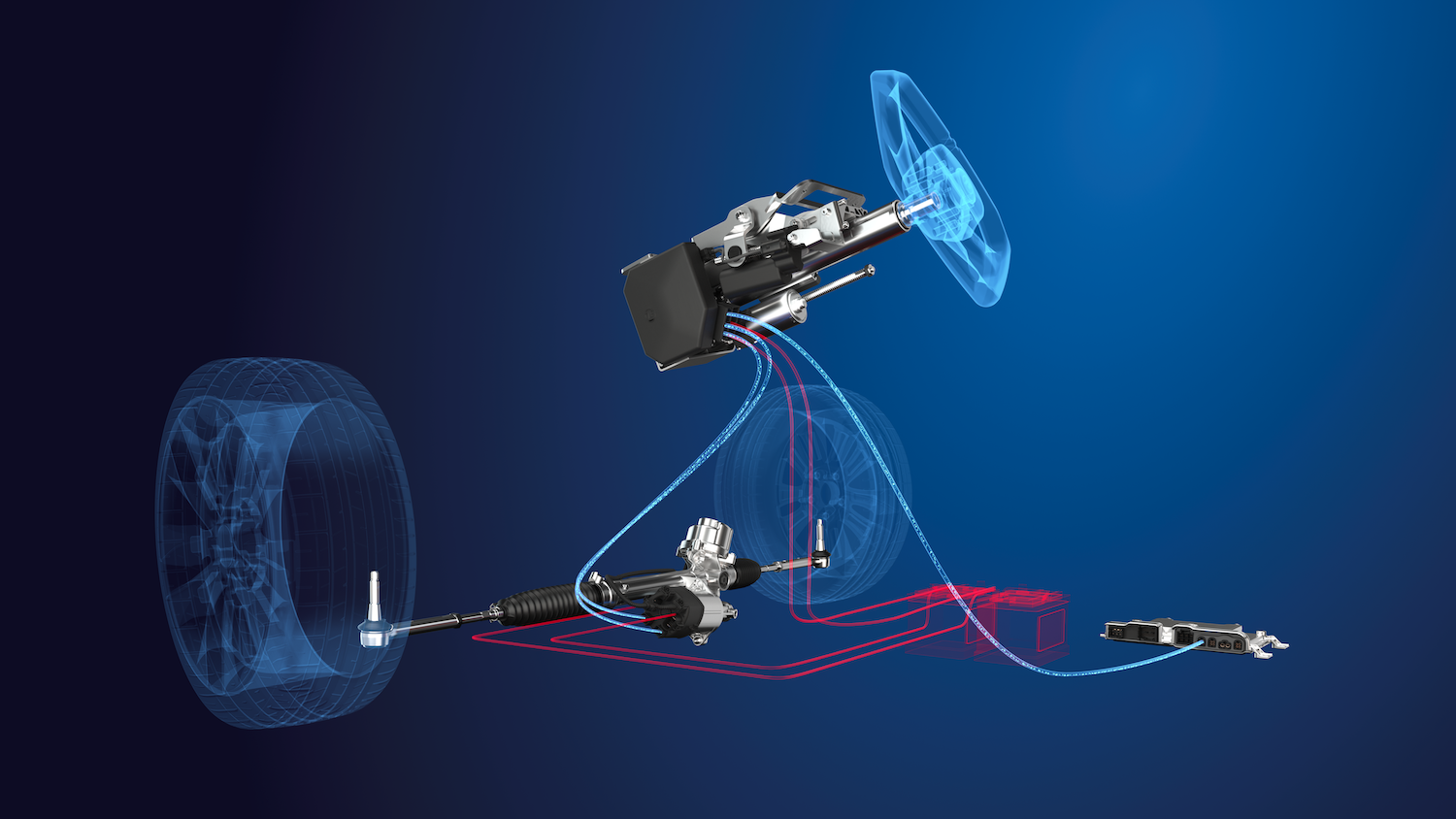

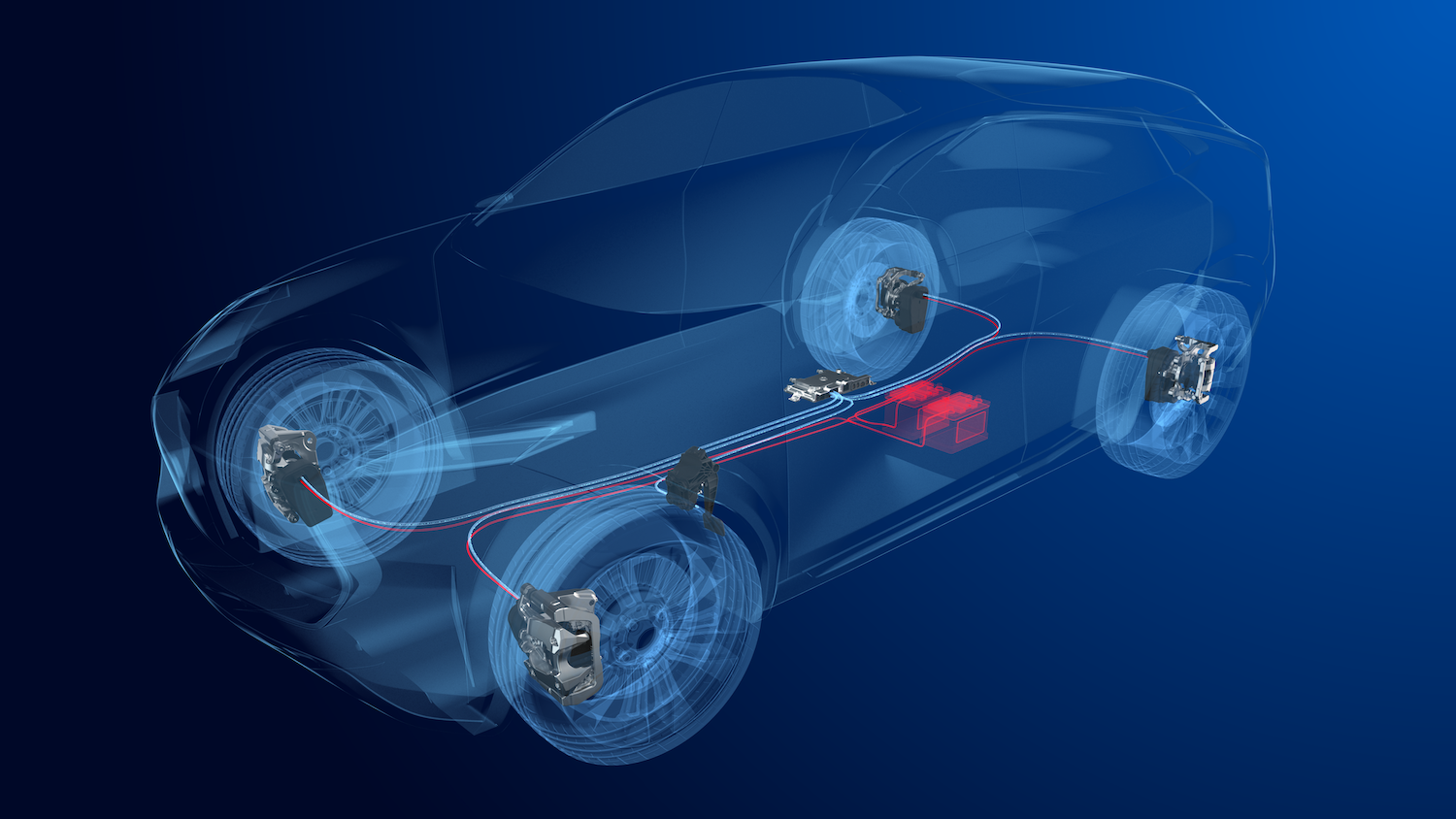

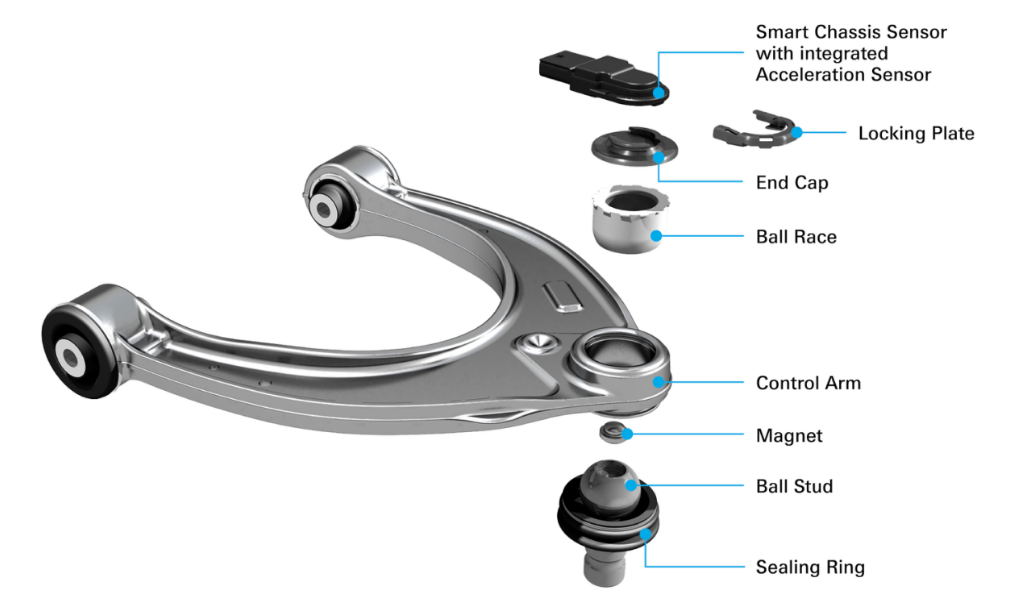

On July 10, ahead of the 2025 International Automobile and Smart Mobility Expo (IAA Mobility), ZF held a Chassis Technology Day event to showcase its technological achievements and strategic positioning in the passenger car chassis business. With the convergence of electric drive, software-defined vehicles, and autonomous driving trends, the strategic value of chassis systems is experiencing unprecedented enhancement. As a leader in global chassis technology, ZF is seizing key opportunities in the industry. Through intelligent actuators, extensive system integration capabilities, and software expertise, ZF is meeting the global demand for innovative driving functions and has secured numerous new orders worldwide. Software-defined vehicles have become a reality. New high-performance central controllers or domain controllers have begun to integrate control functions of multiple components, including critical chassis functions such as braking, steering, and suspension. Dr. Peter Holdmann, ZF Group Board Member and Head of Chassis Solutions, explained: "ZF is benefiting from this trend in two ways. On one hand, the global demand for adaptable components like steer-by-wire and brake-by-wire is expected to continue growing; on the other hand, the market's demand for innovative functions is also strong, as these features enable seamless integration of components, providing significant value to end customers." ZF's "Chassis 2.0" strategy aims to achieve new chassis functionalities driven by software through intelligent interconnected actuators. As part of ZF's chassis solutions product portfolio, these products target the industrialization of steer-by-wire technology, allowing functions like braking and steering to operate without any mechanical connection between the steering wheel and the steering gear or the brake pedal and the braking system. Earlier this year, NIO's ET9 became the first production vehicle in the Chinese market equipped with ZF's full-stack steer-by-wire system. Subsequently, ZF secured orders from two other Chinese automakers and formed a partnership with Mercedes-Benz, aiming for mass production in 2026. The Chassis 2.0 product portfolio also includes active and semi-active suspension systems. The fully active suspension system, sMOTION®, addresses a long-standing challenge in passenger car chassis design: stability and dynamic handling no longer have to come at the expense of comfort, achieving a balance between the two. 25 years ago, ZF launched its first semi-active continuous damping control system, CDC®, which now holds a 40% global market share in this field. In the rear-wheel steering segment, ZF's active rear-wheel steering system, AKC, has an even more prominent market position, with a projected global market share of 73% in 2024, and an impressive 80% coverage in the Asian market. Dr. Holdmann stated: "The Chassis 2.0 strategy precisely aligns with current market demands. By 2030, we expect to achieve approximately 33% market share and €4.8 billion in sales with this series of products, establishing leading positions in both market and technology across all key areas of the Chassis 2.0 product portfolio." ZF's Chassis 2.0 products have gained recognition from various customer groups, as evidenced by the orders already secured from major global and European automotive manufacturers, rapidly growing Chinese automakers, and more flexible new players focusing on niche markets. ZF stands out as one of the few companies in the industry capable of providing specialized software services independently, regardless of whether they supply associated actuators. The core support is the cubiX vehicle motion control software, which uses unified control logic to seamlessly coordinate vertical, lateral, and longitudinal dynamic control of related components. Even if some chassis components in the vehicle are not ZF products, cubiX ensures smooth vehicle operation according to manufacturer specifications. This platform has already been applied in mass production, and based on this, ZF has further introduced the cubiX Tuner. This tool is designed for automakers, offering intuitive operation that automatically calculates the interrelations between actuators. With just a few clicks, it can configure electronic control units according to the manufacturer's unique "brand DNA." This innovative tool provides strong support for engineers working on complex chassis calibration tasks, especially in significantly shortening development cycles. Philippe Gasnier, Head of R&D for ZF's Chassis Solutions Division, explained: "This directly meets the critical demand from all markets, especially customers in the Asian market, for accelerating development processes and reducing costs." As market demands for new chassis functionalities grow, ZF deeply integrates hardware and software technologies, with its latest product, the smart chassis sensor, serving as a prime example. This sensor, integrated into the ball joint, precisely measures the relative motion of the vehicle body. The data collected by this sensor has already been used to control key chassis functions, and this year it has entered mass production on the Cadillac CELESTIQ. ZF's technology upgrades enable this system to capture chassis acceleration in three dimensions. With these high-resolution data, more innovative functions can be realized. For instance, the concept of "chassis health" allows the smart chassis sensor to collect acceleration data, continuously recording the forces acting on the chassis and body, and using algorithms to calculate the potential impact of these forces on chassis functionality in real time. The collaboration of hardware and software has achieved continuous real-time monitoring of the status of chassis components. Data is uploaded from the vehicle to cloud servers through standard interfaces and analyzed using artificial intelligence algorithms. This solution provides critical information about mechanical loads on the chassis and safety-related statuses, effectively acting as a vehicle's "digital health tracker." ZF has integrated the "chassis health" concept into its backend systems, not only enabling data-driven development but also helping to reduce unplanned downtime and maintenance frequency. At the Chassis Technology Day event held in Friedrichshafen, ZF showcased its technical strength and chassis product portfolio through test vehicles and production models. Visitors had the opportunity to experience the NIO ET9 firsthand, which features a feel simulator (providing steering feel), redundant steering actuators, and related software. With these technologies, the vehicle achieves mechanical decoupling between the steering wheel and the front wheels.

ZF Showcases Chassis Technology at IAA Mobility 2025

Images

Share this post on: