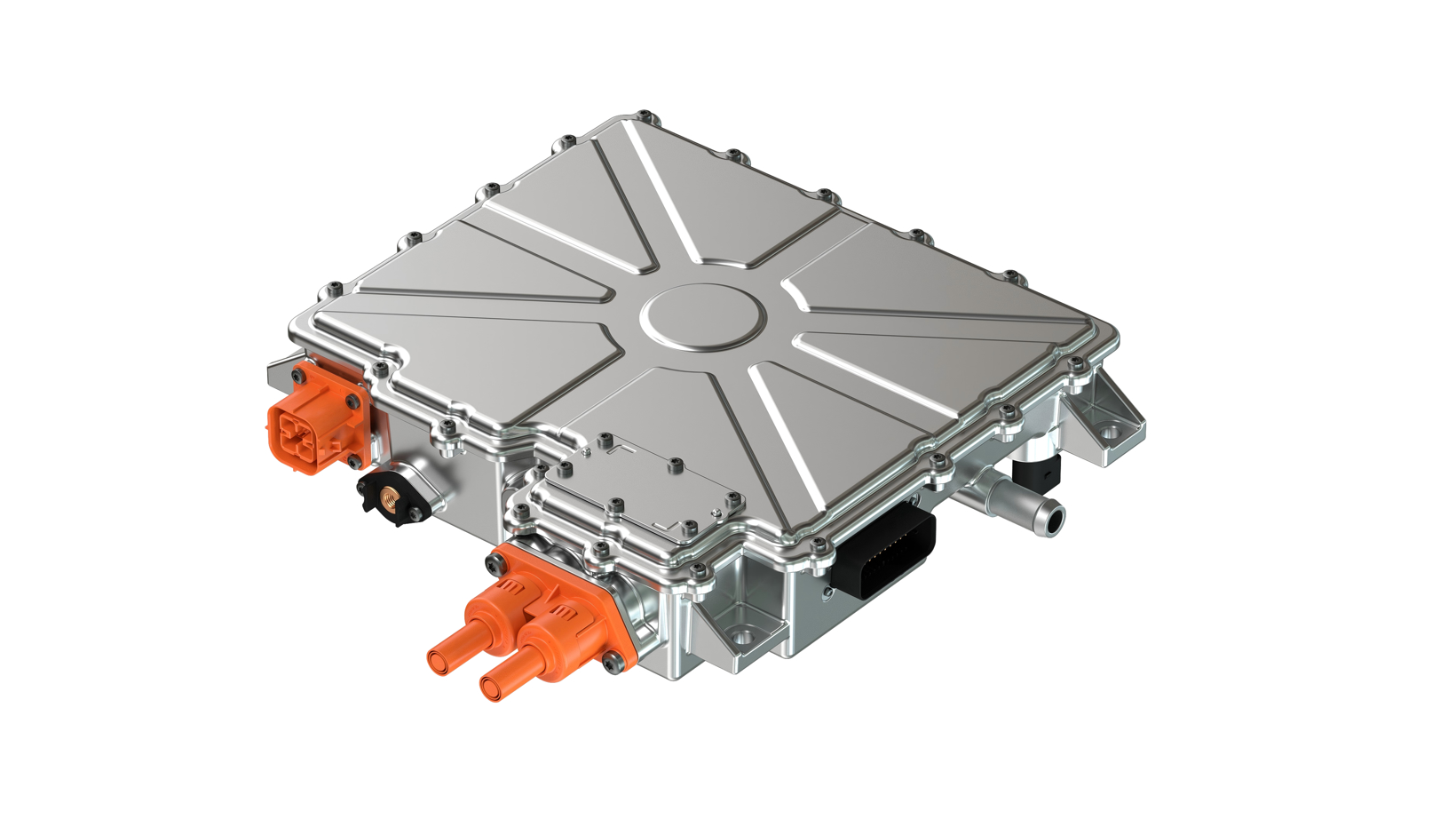

According to the latest news from Valeo, a mainstream Chinese electric vehicle manufacturer has selected Valeo's five-in-one deeply integrated electric drive module for its electric powertrain system. To shorten the development cycle and meet the growing customer and market demands, Valeo has adopted a flexible development process based on advanced research technology stacks, enabling the project to progress from concept to mass production in less than a year, with official production planned to start in 2026. This new solution incorporates advanced technologies such as an inverter, on-board charger (OBC), on-board DC/DC converter, power distribution unit (PDU), and electronic fuse (eFuse) into a deeply integrated electrical and software fusion technology solution. Valeo emphasizes that as the electronic and electrical architecture of vehicles evolves, the compactness, lightweight design, and cost optimization of electric drive and power electronic components have become core customer demands. In line with this trend, Valeo's innovative five-in-one integrated module can achieve approximately 20% weight reduction, supporting the development of next-generation electric drive systems and the evolution of vehicle architecture technologies. Technically, this module relies on a single system-on-chip (SoC) to enable hardware resource reuse for the inverter, DC/DC converter, and gateway controller, reducing system complexity and significantly lowering signal transmission delays and power consumption. It also boasts impressive power performance, capable of delivering 600A RMS continuous AC current on a 400V platform, with peak power reaching 170kW, meeting the demands of high-performance electric vehicle drives, while achieving ASIL C functional safety certification to ensure reliable torque control. In terms of charging compatibility, it supports 7kW/11kW on-board charger (OBC) configurations, adapting to mainstream global charging standards, and integrates a 3kW DC/DC converter module. Additionally, its built-in electronic fuse (eFuse) intelligent protection system reduces failure rates, complies with industry regulations and safety standards, and enhances overall system safety. Notably, the optimized electronic and electrical (EE) architecture design of this module significantly reduces the number of wiring harnesses, wiring length, and weight, improving assembly efficiency for vehicle manufacturers. Regarding cost control, the integration of components reduces system parts costs as well as component development and validation costs. The optimized energy transmission path also greatly reduces vehicle energy consumption.

Valeo's Integrated Electric Drive Module Selected by Major Chinese EV Manufacturer

Share this post on: