The skateboard chassis platform, as a core technology in the architecture of new energy vehicles, is driving automotive design towards modularization and intelligence. This article delves into the current technical status of the skateboard chassis platform, analyzing design challenges, structural optimization, control strategies, and testing methods, presenting key technical details from frame design to intelligent iteration.

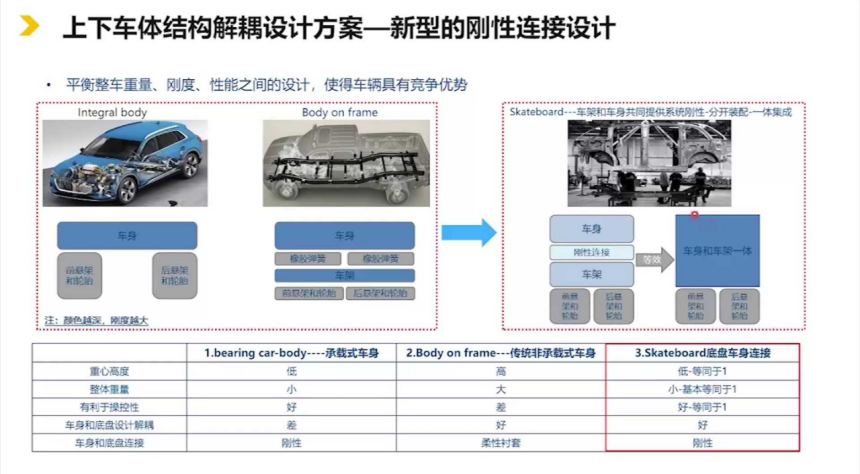

1. Body and Chassis Connection System: Transitioning from Traditional Structures to Rigid Connections

The design of the connection between the body and the chassis is a primary challenge for the implementation of skateboard chassis technology, as its performance directly determines the vehicle's rigidity, vibration transmission characteristics, and collision safety. In traditional body-on-frame structures, the arrangement of connection points, bushing parameters, and load distribution requires repeated iterations. For instance, a project experienced a severe decline in NVH performance and structural cracking after moving the C-pillar connection point forward by 100mm, underscoring the sensitivity of connection system design.

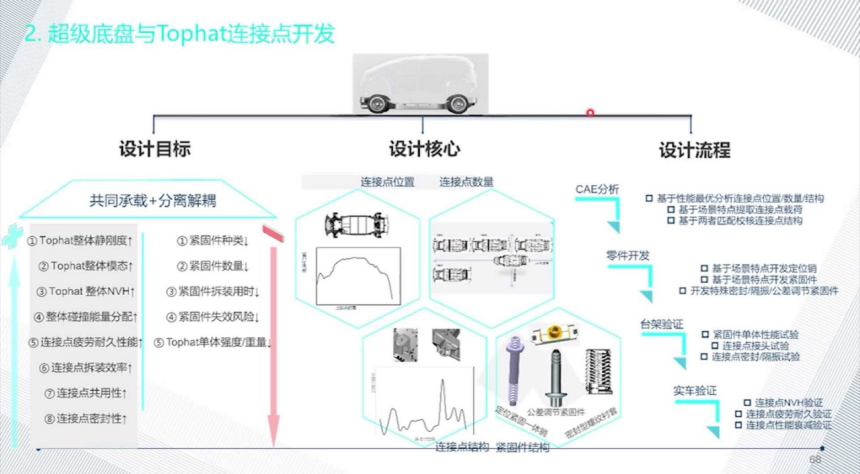

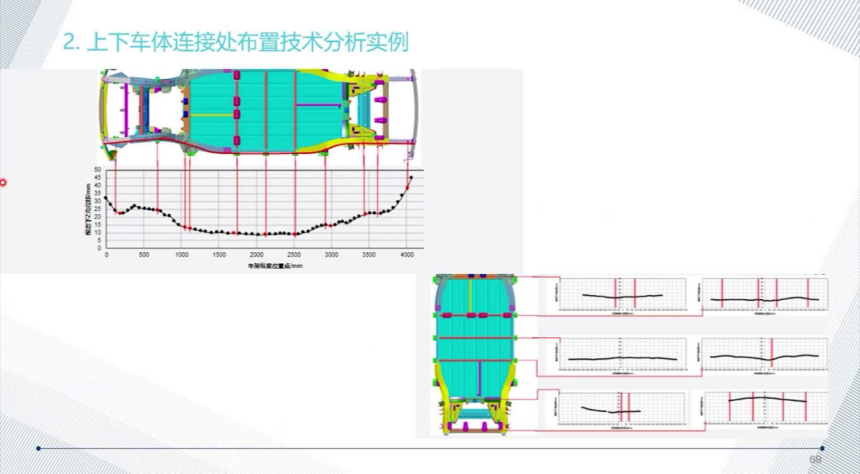

(a) Core Logic and Technical Framework of Connection Point Design

The connection point design must unify the contradictory goals of rigid support and flexible vibration isolation: it must transmit longitudinal and lateral loads through rigid connections while minimizing vibration transfer from the chassis to the body through structural optimization. The design logic can be traced back to traditional body-on-frame structures but must innovate based on the characteristics of the skateboard chassis.

(b) Multi-Level System for Connection Point Performance Verification

Connection points must undergo a full-link verification process covering extreme working conditions, including individual performance tests and system integration tests. Each component must meet rigorous performance standards to ensure structural integrity and safety during operation.

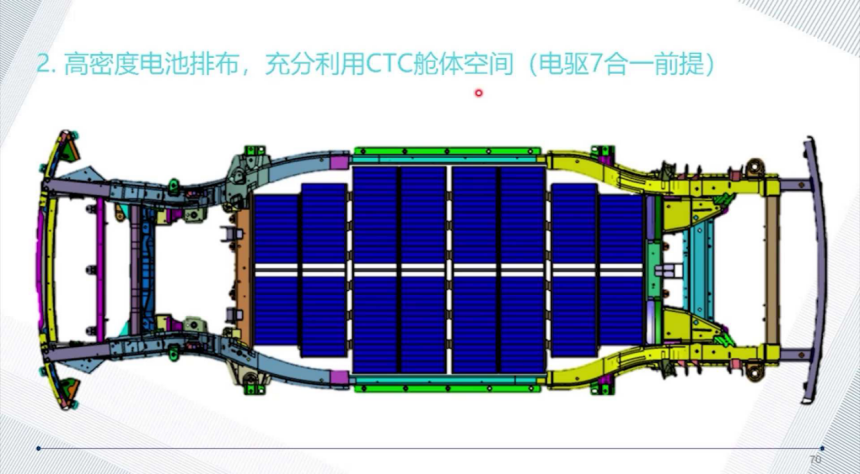

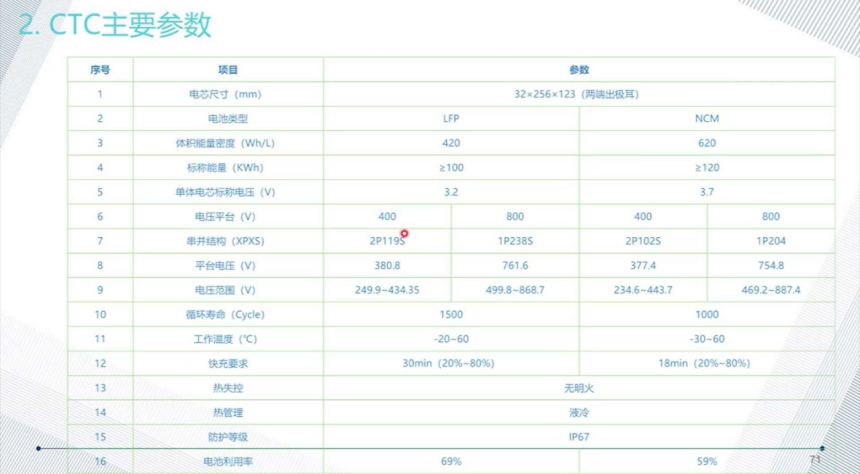

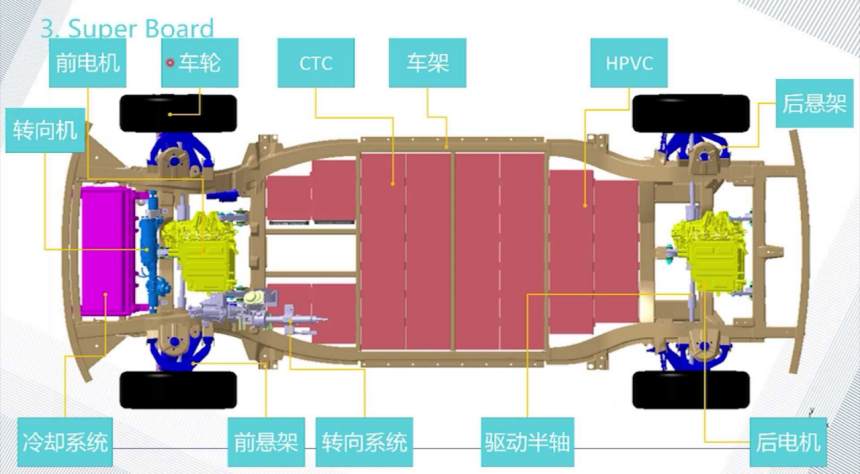

2. CTC (Cell-to-Chassis) Technology: Innovation from 'Battery in Chassis' to 'Battery as Chassis'

CTC technology is a core differentiator of the skateboard chassis compared to traditional electric vehicles, transforming the battery system from an 'add-on' to a 'structural component', achieving lightweight and stiffness enhancement through deep integration with the frame.

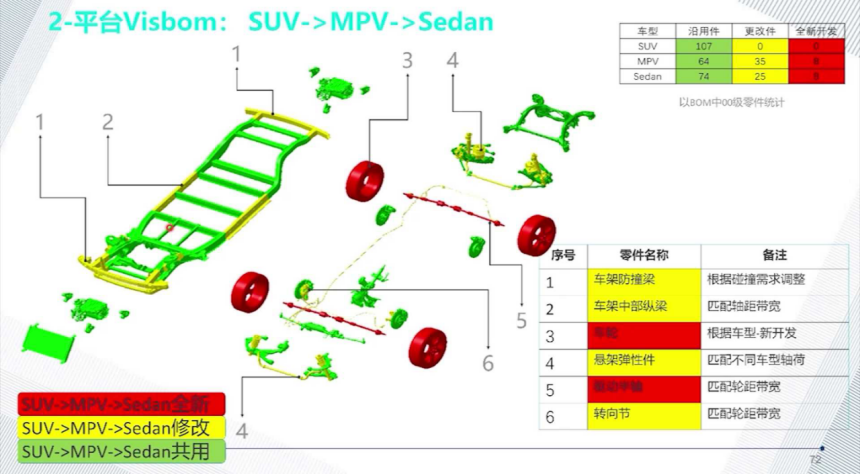

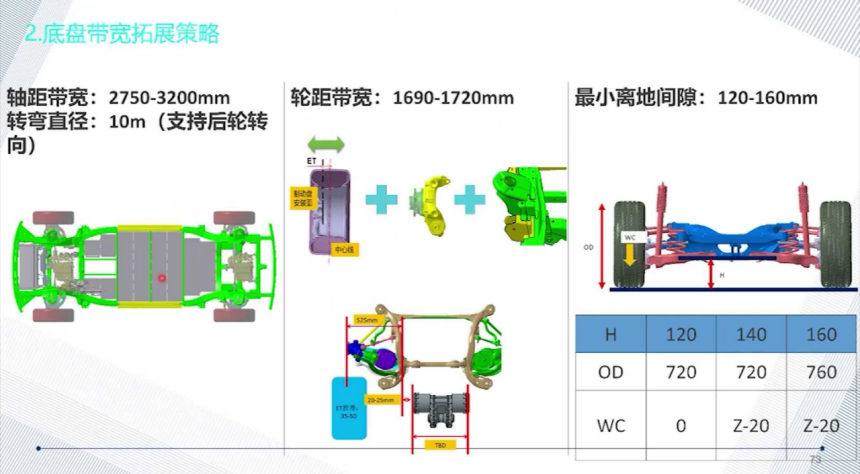

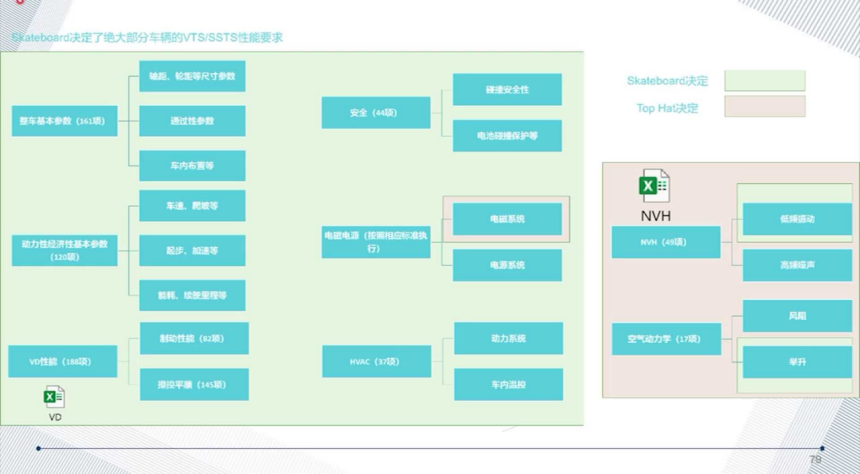

3. Expanding the Chassis Platform's Bandwidth: From 'Single Model' to 'Full Coverage' Flexible Design

One of the core values of the skateboard chassis is to rapidly derive multiple models through standardized architecture, significantly shortening development cycles.

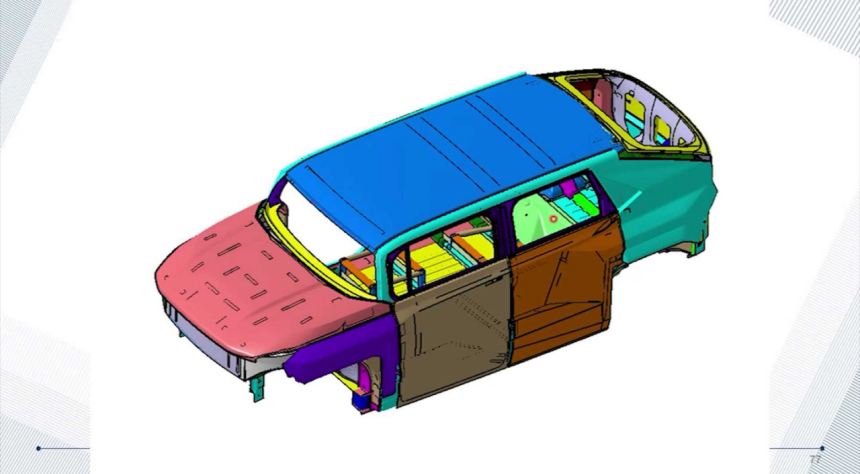

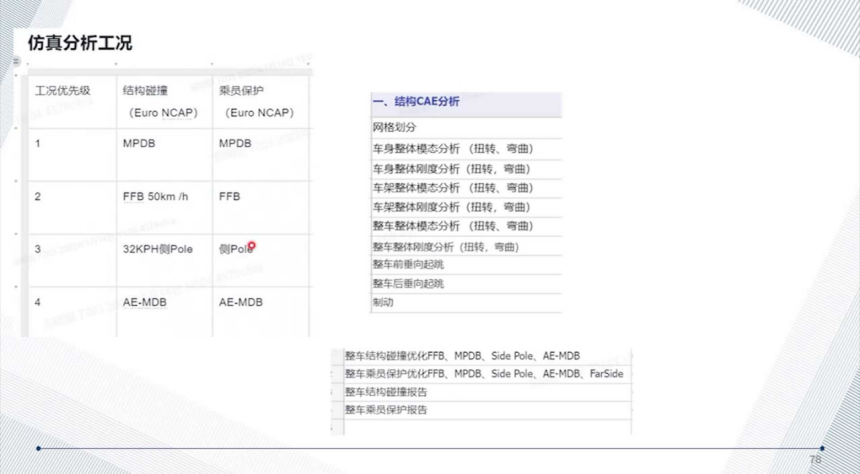

4. Frame Design: The 'Skeleton' of the Skateboard Chassis

The frame is the core load-bearing structure of the skateboard chassis, requiring a balance of crashworthiness, rigidity, lightweight design, and battery protection.

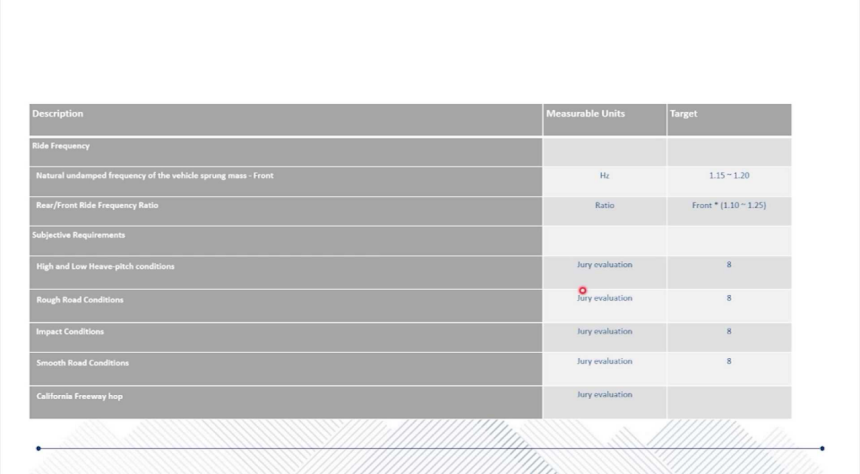

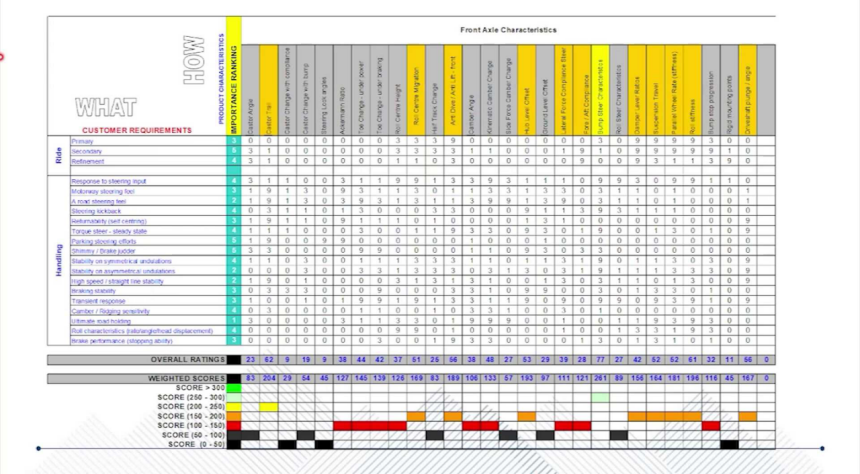

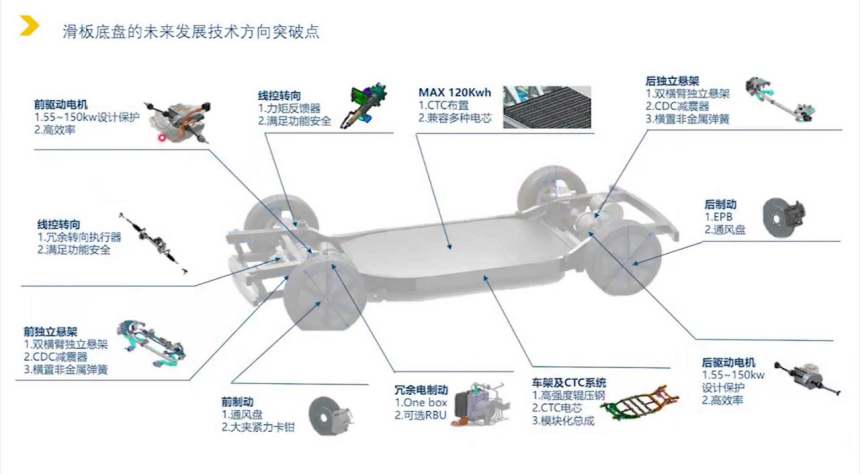

5. Suspension System: Performance Breakthroughs Under Spatial Constraints

The flat design requirements of the skateboard chassis impose stringent challenges on the suspension system, leading to the adoption of innovative structures such as transverse leaf springs and short-arm double wishbones.

6. Electronic and Electrical Architecture and Intelligent Control: From 'Mechanical Coordination' to 'Digital Drive'

The intelligence of the skateboard chassis relies on innovations in electronic and electrical architecture, with the 'three-domain architecture' proposed by Huawei serving as an industry benchmark.

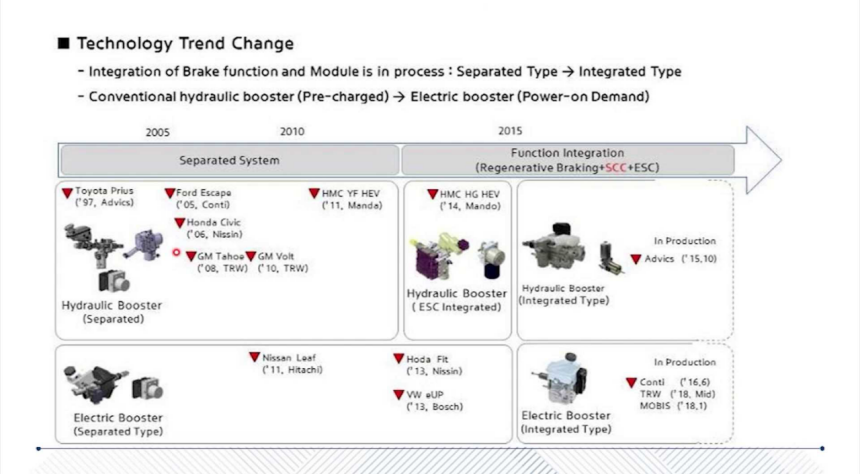

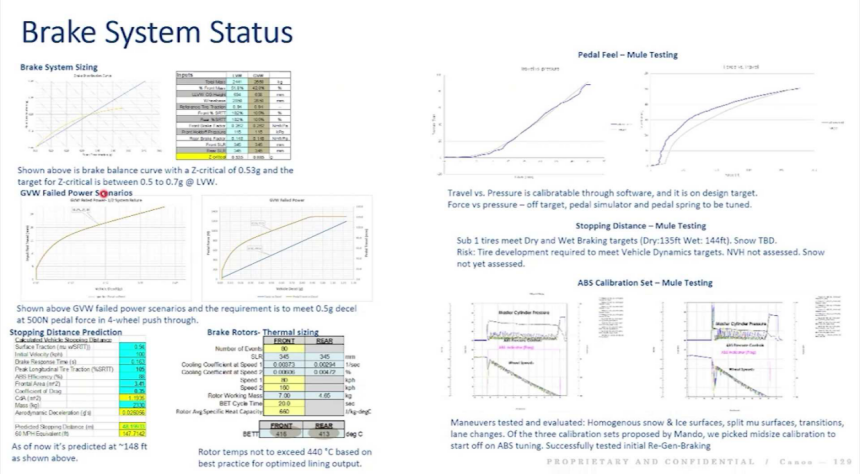

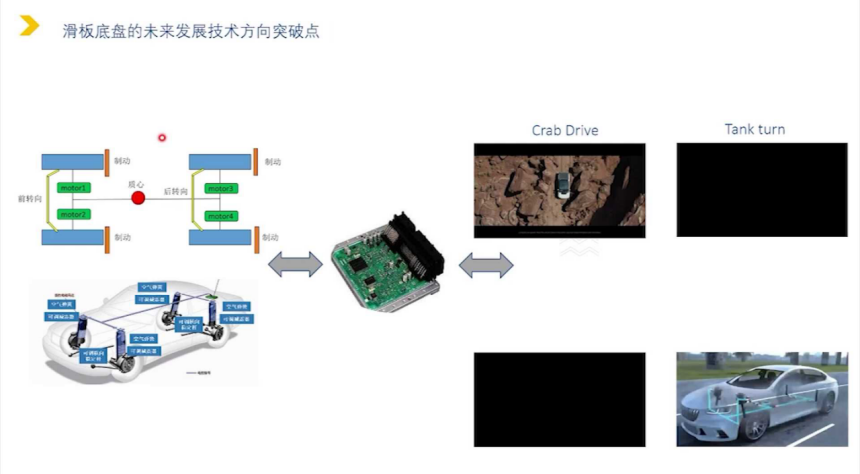

7. Steer-by-Wire and Brake Systems: Safety Assurance in the 'No Mechanical Connection' Era

Steer-by-wire and brake-by-wire systems are crucial for decoupling the vehicle body from the chassis, balancing safety and cost with redundancy as a core requirement.

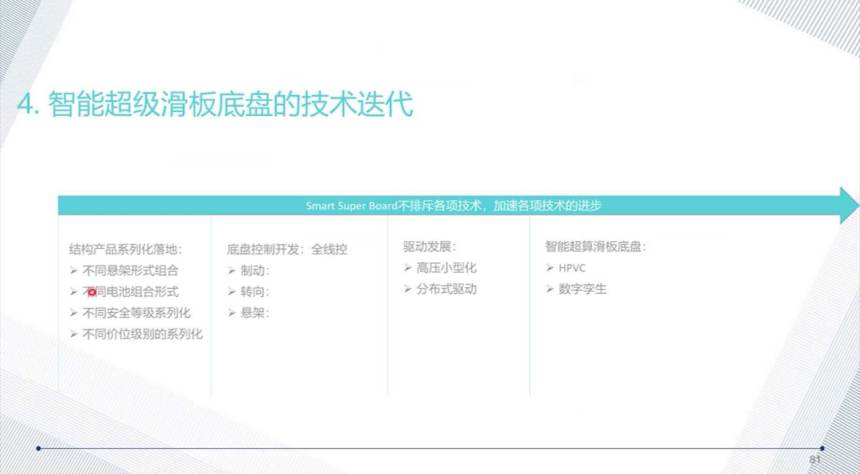

8. Future Evolution of the Skateboard Chassis: Technical Breakthroughs and Industrialization Paths

The future development of skateboard chassis technology will focus on integration, intelligence, and cost reduction, with multiple technical directions moving from the lab to mass production.

Skateboard Chassis Platform: Driving Innovation in Electric Vehicle Design

Images

Share this post on: