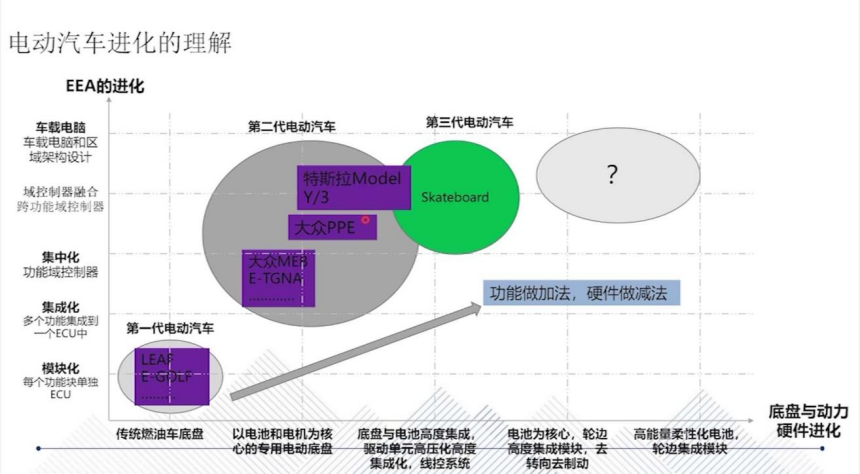

The skateboard chassis has emerged as a new technology amidst the wave of electrification and intelligence in the automotive industry. By decoupling the body and chassis design, it addresses efficiency bottlenecks and cost issues in traditional vehicle development. This article outlines the development history, key technologies, application scenarios, and future challenges of skateboard chassis technology. With the proliferation of electric technology and the intensifying trend of intelligent connectivity, chassis design is shifting from mechanical cores to standardized carriers, and skateboard chassis are expected to reshape the automotive industry landscape, supporting rapid iteration and personalized customization.

1. Technical Background of Skateboard Chassis: The Dual Drive of Electrification and Intelligence

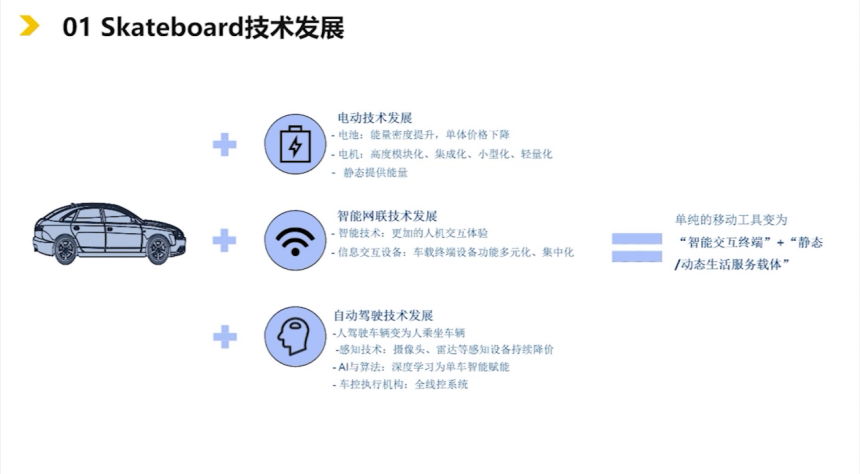

In the transformation of the automotive industry towards electrification and intelligence, the skateboard chassis has gradually come into the industry's view as an innovative chassis structure. This technology's emergence is not coincidental; it is the result of breakthroughs in electrification technology and the trend of intelligent connectivity.

(A) Electrification Technology: Laying the Foundation for Low Center of Gravity Chassis

In the traditional internal combustion engine era, the layout of core components like engines and gearboxes determined the chassis design logic. The height of fuel engines leads to a higher center of gravity, requiring suspension designs that meet both "high passability" and "low posture driving" contradictory demands, which poses significant challenges for structural strength and adjustment precision. The maturity of electrification technology has fundamentally changed this situation. When battery and motor core components are integrated into the chassis, the vehicle's height is significantly reduced, with battery packs typically laid flat on the chassis, forming the baseline for the body. This stability not only reduces the complexity of suspension design but also provides greater flexibility for the overall vehicle layout.

(B) Intelligent Connectivity Technology: Driving the Transformation from "Driving Core" to "Standardized Carrier"

The popularization of intelligent connectivity technology has reshaped user demand for cars. In the past, 70%-80% of consumer attention focused on chassis performance (like handling and power response) and power systems; now, this ratio has reversed to 30% on chassis and power, with 70% focusing on cockpit intelligence (like voice interaction and in-car entertainment) and autonomous driving features. This shift in demand directly promotes the evolution of chassis towards "standardization."

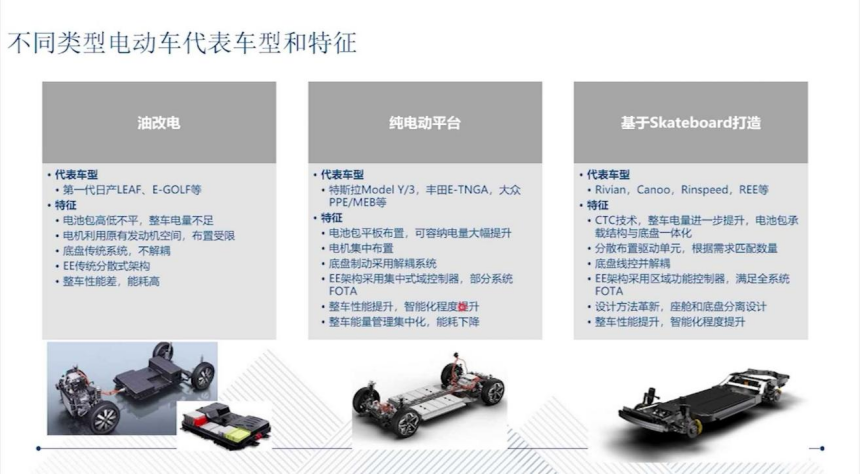

(C) New Power Vehicle Manufacturing Needs: Accelerating the Commercialization of Skateboard Chassis

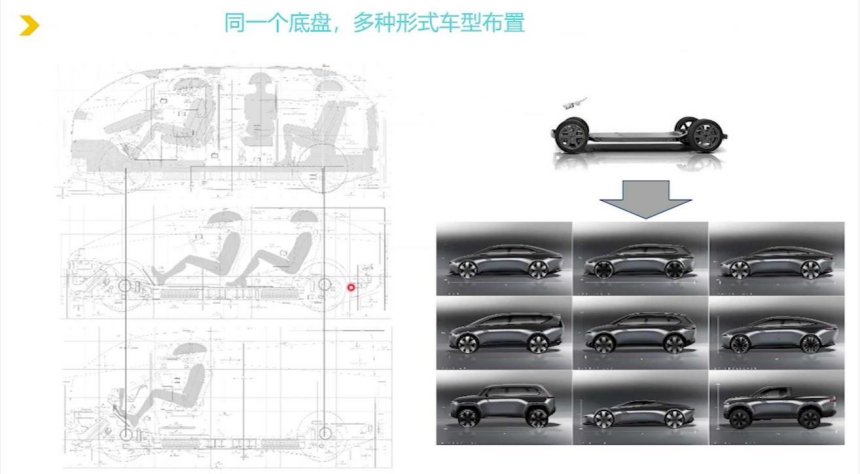

New cross-industry vehicle manufacturers focus more on cockpit design and user experience, emphasizing the need for a "reliable, mature, and rapidly adaptable" chassis. They prefer to see the chassis as a "combination of battery, motor, and mechanical components," investing resources in differentiated cockpit function development. This demand aligns well with the characteristics of the skateboard chassis: a standardized platform that can quickly match different body forms (like SUVs, MPVs, and pickups), significantly shortening the development cycle of new models.

2. Technical Characteristics of Skateboard Chassis: An Innovative Form Between "Non-Load-Bearing" and "Load-Bearing"

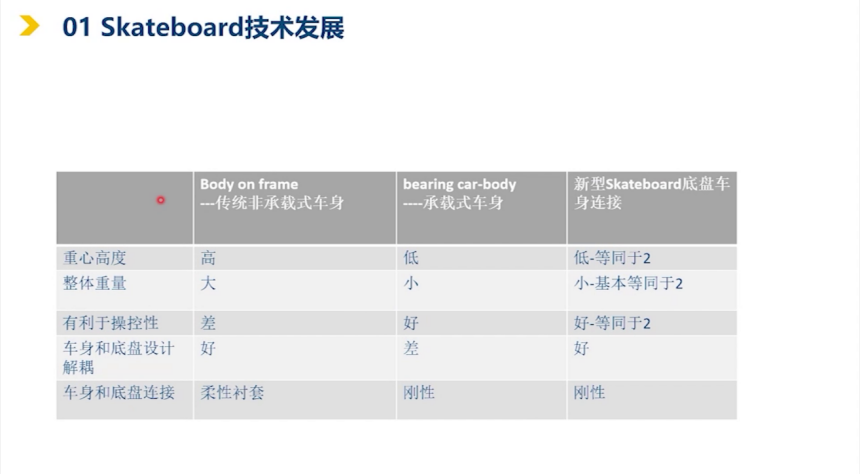

The skateboard chassis is not a product of chance but an optimization and breakthrough of traditional chassis structures. It absorbs the advantages of both non-load-bearing (Body on Frame) and load-bearing bodies while avoiding their shortcomings, forming a unique technological path.

(A) Limitations of Traditional Chassis Structures

Non-load-bearing bodies with independent frames are commonly found in off-road vehicles and pickups. They allow for separate development of the body and chassis for versatile adaptation to various vehicle types; however, they are heavier and have a higher center of gravity, leading to poorer handling and comfort.

(B) Technological Breakthroughs of Skateboard Chassis: Balancing "Rigid Connection + Modular Design"

The core of the skateboard chassis is "separate design of the body and chassis + rigid integrated connection." Its technical characteristics include functional integration, rigid connection, and a balance between weight and rigidity. It maintains the flexibility of non-load-bearing bodies while offering the advantages of load-bearing designs, particularly suitable for small-volume, diverse model development.

3. Core Advantages of Skateboard Chassis: A Solution Adapted to Industry Trends

The value of skateboard chassis lies not only in technological innovation but also in its precise adaptation to automotive industry trends like shortened development cycles, accelerated iteration speeds, and increasing personalized demands. Its core advantages are:

(A) Shortened Development Cycles and Reduced Transformation Costs

The modular design allows for separate development of the chassis and body, reducing the new model development cycle significantly.

(B) Enhanced Model Adaptability

The separate design allows quick adaptation to various body types, addressing traditional platform issues.

(C) Supporting the Implementation of Intelligent and Line-Controlled Technologies

Skateboard chassis serve as ideal carriers for line-control technologies, offering standard interfaces compatible with centralized domain controllers.

(D) Balancing Personalization and Standardization Needs

As autonomous driving and niche consumption trends evolve, the skateboard chassis model allows for a combination of standardized chassis and customized cockpits, meeting diverse consumer needs.

4. Challenges and Industry Practices of Skateboard Chassis Development

Despite its advantages, the commercial realization of skateboard chassis faces technical, cost, and ecological challenges. Industry pioneers like Rivian and Canoo are already exploring these avenues, indicating a trend toward widespread adaptation of skateboard chassis technology.

5. Skateboard Chassis — A Pivot for Automotive Industry Transformation

The emergence of the skateboard chassis marks a significant shift in the automotive industry from mechanical drive to electric intelligence. It is a balanced solution that adapts to the multi-faceted needs of electrification, intelligence, and personalization. As line-control technology matures and costs decrease, skateboard chassis may become a mainstream chassis form, reshaping the competitive landscape of the automotive industry.

Skateboard Chassis: A Transformative Technology in the Automotive Industry

Images

Share this post on: