On July 21, Nanjing North Road Intelligent Control Technology Co., Ltd. announced that it has signed a project investment agreement with the Nanjing Jiangning Binjiang Economic Development Zone Management Committee. The company plans to invest 600 million yuan to establish a "Smart Mining Driving Industrial Base Project." This project aims to promote the intelligent transformation of mines through the research and development of smart driving systems and autonomous mining trucks. The overall investment is expected to be completed within five years, and after full production by 2030, the annual output value will exceed 800 million yuan, with a tax contribution of about 40 million yuan. Currently, significant progress has been made in smart mining driving technology. For example, Yikong Zhijia's unmanned mining trucks have been deployed in open-pit coal mines in Xinjiang and Inner Mongolia, with over 1,400 units in operation, covering various types of mines such as coal, metal, and limestone, achieving nearly 50% market share. By utilizing its independently developed "Yushi" new energy line control platform and "Zhuoshan" distributed technical architecture, Yikong Zhijia has enabled efficient collaborative operations of over 400 unmanned mining trucks in a single mine, with vehicles ready for production in as little as three days. Individual unmanned trucks have achieved operational mileage exceeding 30,000 kilometers, with transportation efficiency reaching over 80% compared to manual driving. On the policy front, both national and local governments are actively promoting the intelligent transformation of mines. At the national level, documents such as the "Guiding Opinions on the High-Quality Development of Open-Pit Coal Mines" clearly state that by 2025, open-pit coal mines should achieve intelligent continuous operations and unmanned transportation, with the proportion of intelligent production capacity in coal mines nationwide not less than 60%. At the local level, regions like Xinjiang, Inner Mongolia, and Shanxi are actively responding to push for the implementation of mining intelligence timelines. Market data indicate that the number of unmanned mining trucks in China's open-pit coal mines will reach 2,500 by 2024, a growth of over 120% compared to 2023, and is expected to exceed 5,000 by 2025, with a penetration rate of 20%. The commercial value of smart mining driving has been widely recognized. For instance, in the Xinjiang Tianchi Energy South Open-Pit Coal Mine, out of 370 unmanned mining trucks, 310 are extended wide-body vehicles, achieving "no safety personnel" operation, with cumulative transportation volumes ranking among the industry leaders. Through remote scheduling from a smart cloud control center, combined with high-precision mapping and positioning technologies, accident rates have significantly decreased, and operational costs have been reduced by 30%. The application in Tongling Conch Limestone Mine also validates the effectiveness of this technology, where 24 unmanned mining trucks replaced 24 drivers, requiring only four maintenance personnel, with a total transportation volume exceeding 10 million tons and single-line efficiency reaching over 85% of manual operations. Technological iteration and ecosystem construction will be core to future development. The integration of technologies such as 5G, AI, and vehicle-road-cloud systems is advancing smart mining driving towards "fully unmanned mines." Zhunneng Group is piloting "5G + unmanned trucks, remote-controlled electric shovels, and intelligent engineering auxiliary equipment" for collaborative operations through 5G network upgrades, achieving regional unmanned production. Meanwhile, the industry standard system is gradually improving, with seven departments including the National Mine Safety Administration jointly issuing guiding opinions to establish a complete set of intelligent standards by 2026. The formation of a collaborative ecosystem of production, learning, research, and application accelerates the adaptation of technology and resolution of data security issues, laying the foundation for full-process intelligence. The construction of Nanjing North Road Intelligent Control's industrial base comes at the eve of industry explosion. By introducing cutting-edge technologies such as explosion-proof new energy line control vehicles and intelligent perception in complex underground mining environments, the project will strengthen the company's core competitiveness in the smart mining field. This model of "technology research and development + mass production" not only responds to policy calls but also meets the urgent market demand for efficient, safe, and green mining solutions.

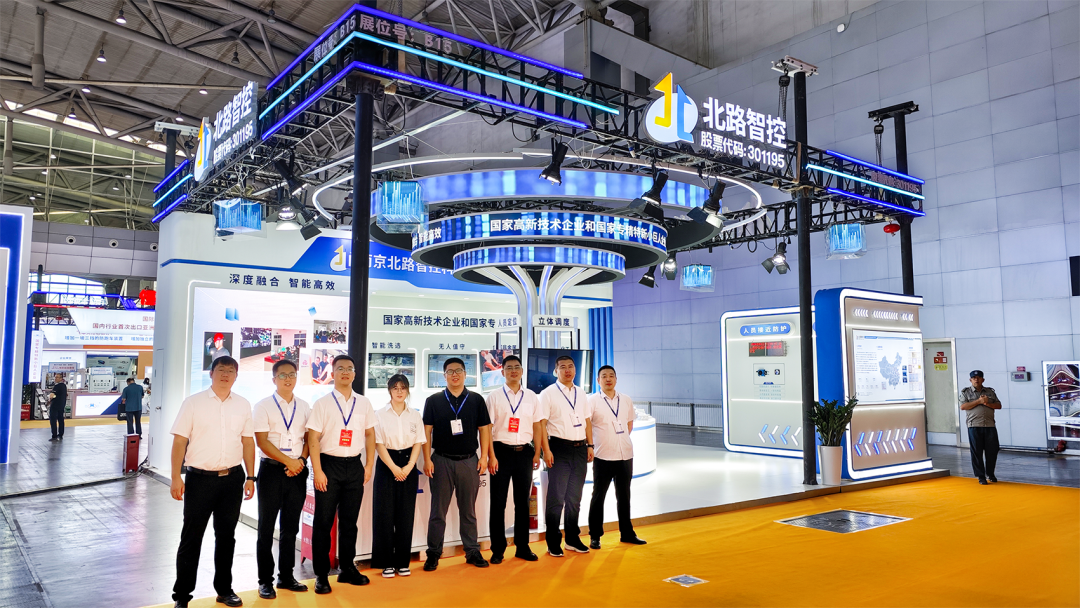

Nanjing North Road Intelligent Control Technology to Invest 600 Million Yuan in Smart Mining Driving Industrial Base

Share this post on: