On July 22, 2025, during the 8th Intelligent Assisted Driving Conference, Zheng Songyue, the Technical Director of IPG Automotive Equipment (Shanghai) Co., Ltd. (hereinafter referred to as IPG), emphasized the increasing application of simulation testing in the automotive sector. While real vehicle testing still dominates, simulation testing demonstrates unique value in functional and performance testing. Advances in technology, particularly the decrease in computing costs and improvements in graphics card performance, have made physical sensor solutions feasible, further promoting the development of simulation testing. The introduction of AI technology provides new ideas for the autonomous exploration and traversal of test scenarios, improving testing efficiency and quality. Zheng mentioned that the concept of 'left-shifting' originates from the trend of 'software-defined vehicles,' emphasizing the need for testing work to align more closely with the development phase to enable continuous testing and early defect detection. IPG supports customers in enhancing testing efficiency and quality through its left-shifting solutions at both the V-model and timeline levels, including the introduction of virtual controllers, various Hardware-in-the-Loop (HIL) testing solutions, and software tool support. Additionally, IPG explores the integration of indoor and outdoor Vehicle-in-the-Loop (VIL) testing, providing new pathways for simulation testing in intelligent assisted driving.

Zheng introduced IPG, a German company established in 1984, which entered the Chinese market relatively late. Initially focusing on vehicle dynamics and HIL simulation, the company has continually evolved to offer innovative solutions in response to industry trends. Currently, IPG provides a range of products and services, including self-developed software like CarMaker, TruckMaker, MotorcycleMaker, and hardware products like Xpack4, alongside test systems built on software and hardware.

When discussing HIL, many may wonder about the differences between IPG's Xpack4 and offerings from dSPACE and NI. Before the introduction of ADAS, there was a clear division of labor within the industry, with dSPACE focusing on powertrain, IPG on vehicle dynamics, and NI having a broader application base not specifically designed for automotive use. The emergence of ADAS marked a turning point in the industry, leading to a competitive influx into this new application market. ADAS HIL testing requires fewer board card demands, primarily involving communication boards such as CAN, LIN, Flexray, and Ethernet. The core shift in ADAS HIL testing has become sensor solutions, focusing on how to achieve sensor simulation or emulation.

As a market leader, IPG was the first to propose video injection solutions and ultrasonic echo simulation, although it does not engage in millimeter-wave and lidar echo simulation, relying on partners for those services. In the hardware sector today, the differences among NI, dSPACE, Vector, and others regarding board cards are minimal, with the competitive focus shifting toward software solutions.

In software, IPG offers a comprehensive suite of models, providing solutions based on Model-in-the-Loop, Software-in-the-Loop, Hardware-in-the-Loop, Vehicle-in-the-Loop, and cloud integration. The application of simulation testing is trending in the automotive industry, where most manufacturers focus primarily on real vehicle testing, leading to varying perceptions of simulation testing's value. While customers desire to reduce reliance on real vehicle testing through simulation, achieving a seamless integration from simulation to real-world testing will require significant industry effort.

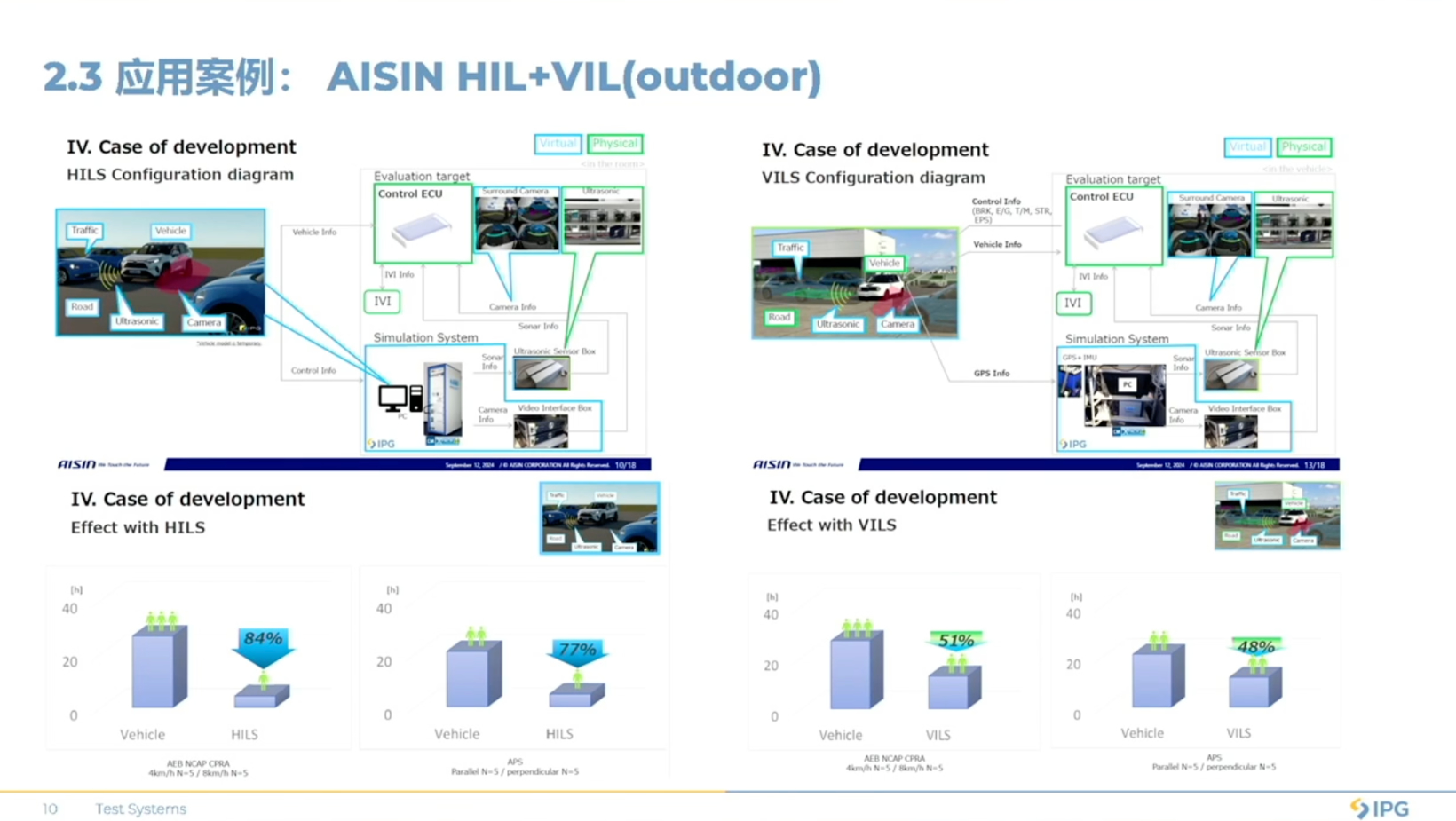

With the new Euro NCAP regulations in 2026, simulation testing can help achieve higher scores, particularly in the safe driving and crash avoidance modules, with some simulation tests available for third-party assessment. Examples from the 2024 IPG user conference include Aisin, a Japanese company that has achieved high consistency in test cases from HIL to VIL and real vehicle testing stages, effectively controlling costs and reducing personnel requirements.

In the testing field, testing can generally be divided into verification and validation. However, there are often doubts regarding the authenticity of functional testing. Customers frequently question the value of simulation testing if it cannot replace real vehicle testing. Although current technological conditions limit the realization of this expectation, advancements in computing power and graphics card performance have led to physical sensor solutions becoming more common.

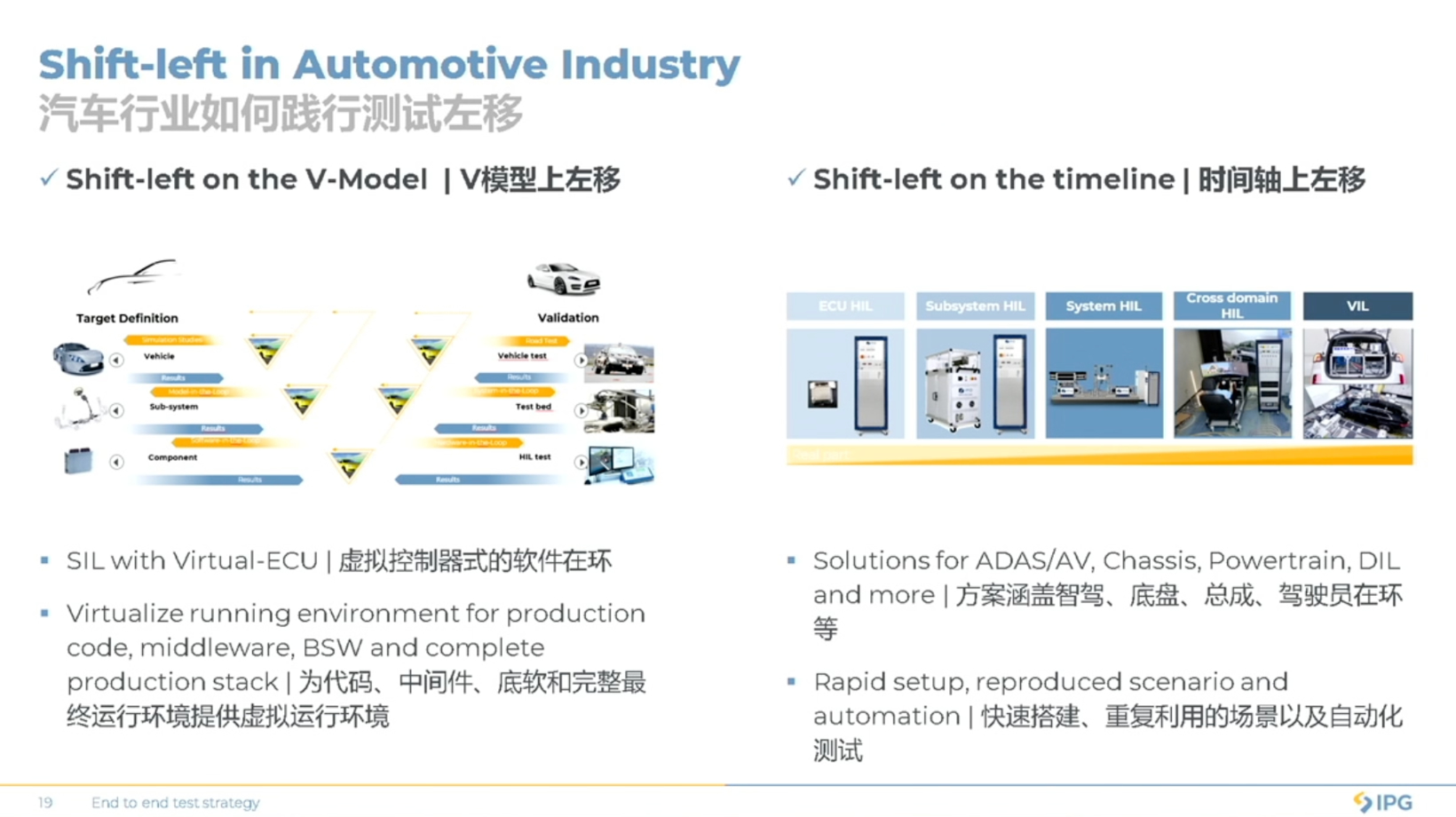

Zheng emphasized the importance of the 'left-shift' concept, which aligns with the trend of software-defined vehicles. As hardware differences among vehicle models diminish, software remains a key factor in functional performance. The traditional automotive industry experiences significant differences in testing processes, leading to the 'left-shift' concept aimed at early defect detection and continuous testing throughout the development lifecycle.

To achieve this, collaboration among development, testing, and operations teams is crucial, enabling more frequent and efficient testing. While challenging, this methodology can bridge gaps between development and testing, significantly enhancing testing efficiency and quality. Zheng proposed two approaches for realizing the left-shift: one through the V-model and the other through the testing timeline.

In V-model left-shifting, the introduction of virtual controllers is key, while various HIL testing solutions support the timeline left-shift. IPG's software tools, including CarMaker Office, CarMaker Extended, and CarMaker HIL, aim to assist customers in integrating virtual Electronic Control Units (ECUs) with various test rigs. In the realm of virtual vECUs, there are signal-based and message-based modes, allowing communication through virtual buses rather than direct API calls.

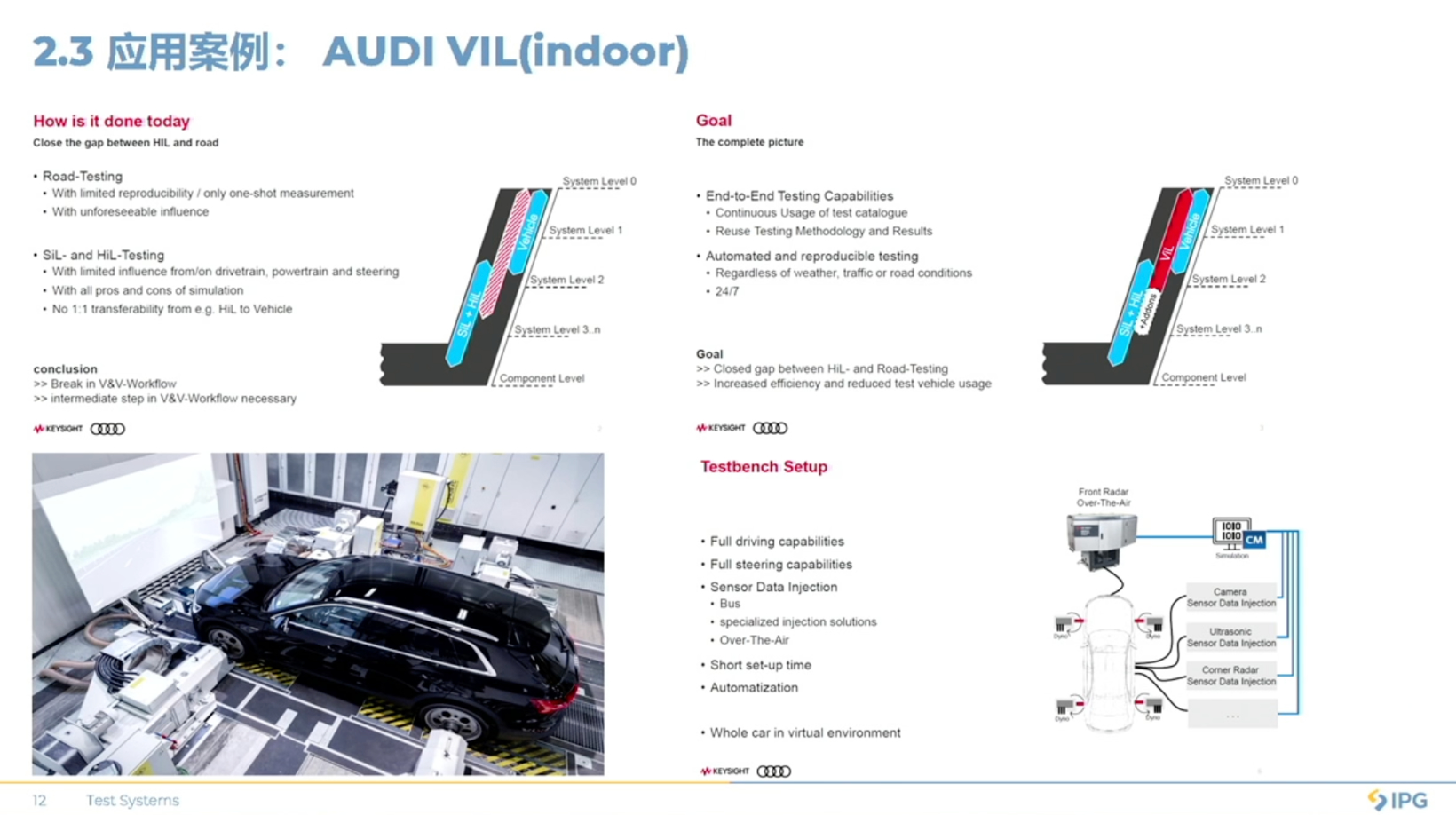

HIL testing encompasses ECU-level, subsystem-level, and system-level tests, corresponding to different teams responsible for the tested components. Cross-domain HIL testing integrates various systems for comprehensive testing, while vehicle-in-the-loop testing includes both indoor and outdoor forms. A successful proof-of-concept project has explored combining outdoor and indoor VIL testing, showing how vehicles and sensors can be integrated for effective testing without collision risks.

In indoor VIL testing, vehicles can be subjected to high-speed tests without the need for large spaces, and driving robots can control the vehicles, eliminating the need for human drivers. Future discussions in the industry will center on end-to-end testing solutions, especially regarding the integration of simulation and real data, which remains a topic for further examination.

IPG Highlights Growing Role of Simulation Testing in Automotive Industry

Images

Share this post on: