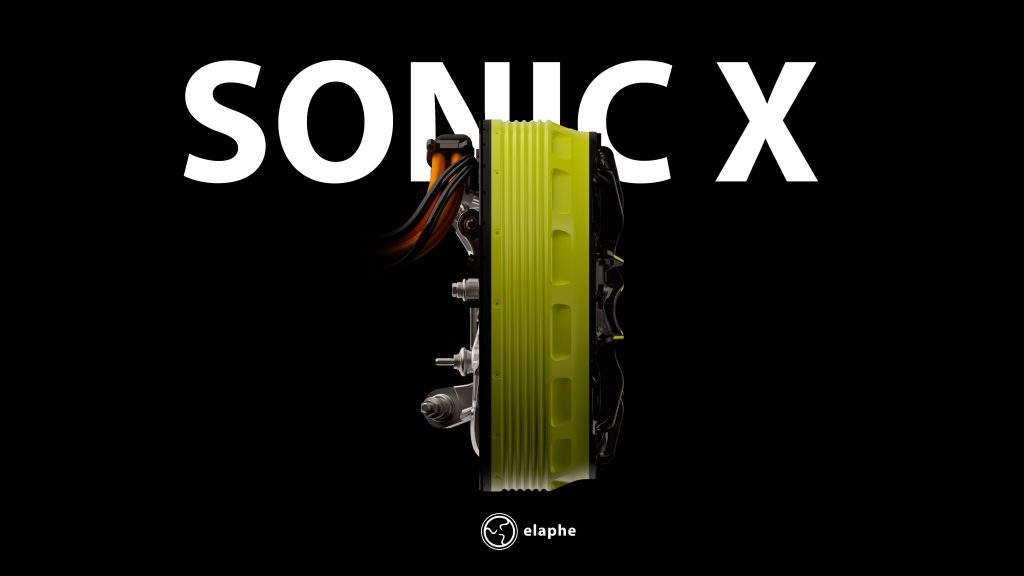

On July 7, Elaphe, a global leader in hub motor technology and wheel control, announced the launch of its innovative high-performance hub motor system product platform, Sonic X. Following the introduction of the world's first high-performance front hub motor Sonic.1 at CES 2025 six months ago, Sonic X represents a new high-performance product platform designed for hybrid and electric vehicle architectures, promising significant performance upgrades for both new and existing models. The system offers unmatched direct drive power density and advanced control capabilities in a lightweight package, and is directly compatible with high-performance brake systems and existing high-end automotive architectures. The Sonic X drive technology aims to add over 300 kW of power to each wheel while minimizing weight increase, regardless of the vehicle's powertrain base. The Sonic X platform is compatible with standard high-performance brake systems, allowing large brake discs to be integrated into wheels ranging from 20 to 23 inches, making it an ideal choice for enhancing torque in high-performance vehicles where space and weight are critical factors. Directly integrating the Sonic X hub system into the wheels not only optimizes vehicle space and weight but also enhances wheel handling. The wheel control speed of Elaphe's direct drive solution is 20 times faster than traditional electric drive systems, elevating traction control and lateral dynamics to a new level, improving performance by 15% and providing more driving enjoyment through quicker cornering speeds. Samples of Sonic X will be available to automotive manufacturers in the first quarter of 2026. The Sonic X high-performance hub motor platform features gearless torque transmission and high-speed wheel control capabilities. Built on the Sonic X high-performance product platform, the hub motor system consists of a direct drive hub motor (gearbox-free), power electronic devices, and embedded proprietary high-speed control software for managing powertrain and vehicle dynamic functions. The torque and power-dense hub motor can be scaled to fit 20 to 23-inch wheel sizes. An onboard high-power SiC inverter, packaged in compact sizes (16 liters), is equipped with proprietary Elaphe high-speed control software, providing motor control, wheel slip control, and vehicle dynamics functions (brake blending and optional torque vectoring). When integrated with hybrid vehicle drivetrains, the software also offers mechanical differential control. Key features of the Sonic X-based hub motor system include: lightweight performance design with unmatched direct drive power density exceeding 8 kW/kg and torque density up to 80 Nm/kg; track-level braking capability with integrated large friction brake discs (350 mm–420 mm) and high-power brake blending technology to ensure high-performance braking while reducing brake temperatures and shortening stopping distances compared to pure friction braking; advanced Elaphe skid control system enhancing acceleration and deceleration performance by 15% and cornering speed by 5%; ease of integration compatible with all existing vehicle architectures (400 V or 800 V), enhancing performance for internal combustion engines to pure electric vehicles, and customizable for main drive systems; compatibility with standard performance wheel components and suspension geometries; optimized onboard space suitable for high-performance vehicles with limited space, occupying only 10% of the footprint while delivering high-performance dual-bridge power; and Elaphe Vibroacoustics, an industry-first proprietary feature that controls the real sound and vibrations of the hub motor, adjustable for complete silence or amplified sounds to enhance feedback and driving experience. The scalable technology supports up to 1 MW peak power per axle and peak torque of up to 9000 Nm when used in rear-wheel drive, with hub size range from 20 to 23 inches. The design freedom allows for new designs from improved aerodynamics to component layout and styling by reducing the number of onboard components (approximately 100 liters).

Elaphe Unveils High-Performance Hub Motor Platform Sonic X

Share this post on: