Thermal management technology for new energy vehicles is evolving towards precision and intelligence. Under extreme climate conditions, the energy consumption of traditional air conditioning systems can account for up to 40% of the total vehicle energy consumption, becoming a core pain point affecting the range of electric vehicles and passenger comfort. According to Wu Huimin, Director of Application Engineering and Project Management for Asia at Gentherm, the company has decades of experience in thermal comfort and aerodynamic comfort. Their ClimateSense system not only considers zoned control of traditional air conditioning but also integrates heating components such as seats and steering wheels that directly contact the human body, achieving more refined temperature management. Through virtual sensor technology and real-time data feedback, the system can accurately calculate the surface temperature of seats and coordinate with the overall vehicle control to optimize energy consumption and enhance passenger thermal comfort. Wu emphasized that Gentherm also focuses on battery thermal management and temperature management technologies in the medical field, further enriching its knowledge base in human thermal regulation, which feeds back into the smart temperature control system. With wearable measurement systems, Gentherm can evaluate passengers' thermal comfort status in real time, providing data support for product optimization.

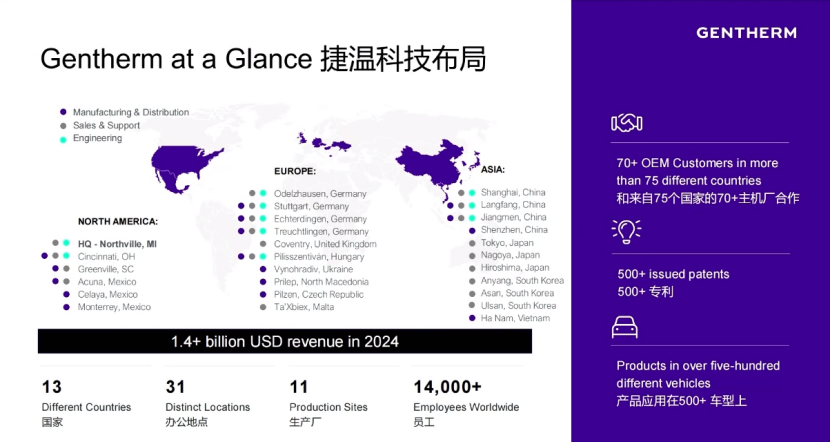

Gentherm Technology, a global leader in thermal comfort, expects revenue to reach $1.4 billion in 2024, with 31 branches in 13 countries across three continents, 11 production bases, and 14,000 employees. The company has been deeply involved in automotive thermal management for decades, collaborating with over 70 OEMs and covering 75 countries, with more than 500 patented technologies applied to over 500 vehicle models. Its Asian headquarters is located in Shanghai, with engineering centers in Shanghai, Langfang, and Jiangmen, and manufacturing bases in Langfang, Tianjin, Shanghai, Henan, and Japan/Korea.

Gentherm's sustainable development strategy is built on four pillars: 'People-Oriented, Caring for the Earth, Giving Back to the Community, and Product Innovation.' 92% of its production bases have obtained ISO14001 certification, and its North American and European factories achieve 100% renewable energy supply. In 2023, the company was recognized as the most responsible company in the U.S. by Newsweek. The core business focuses on five areas: Climate Comfort (temperature-controlled seats/interior heating), ClimateSense, Pneumatic Comfort (pneumatic massage lumbar support), Battery Performance (battery heating films/fans), and Medical (patient temperature management), forming a technology closed loop driven by electronic software systems.

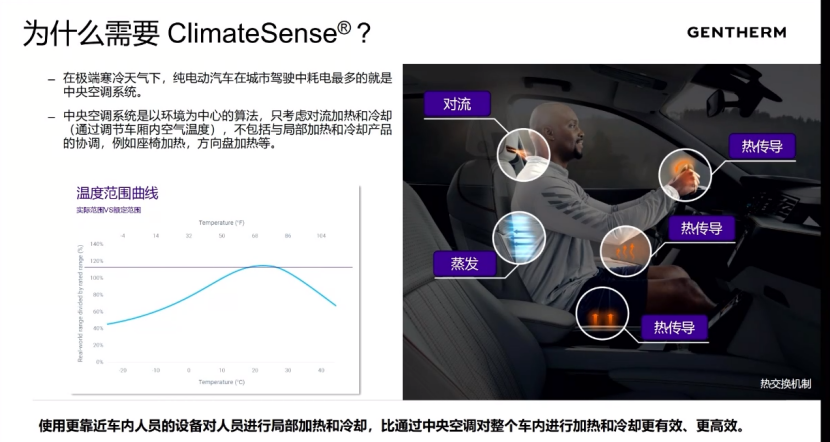

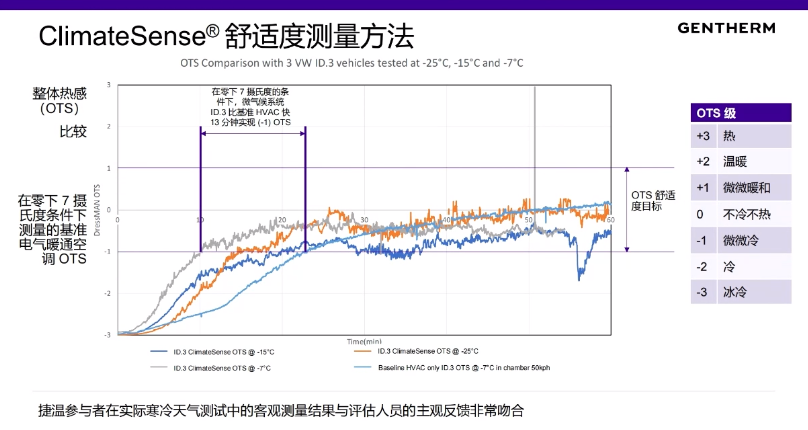

The ClimateSense system addresses the pain points of electric vehicles under -20°C conditions, where traditional air conditioning can consume up to 40% of energy due to its reliance on a single temperature control mechanism of air convection. Human thermal exchange actually includes four pathways: conduction (heat transfer from seat contact), convection (air-conditioning airflow), radiation (infrared radiation from heating devices), and evaporation (sweat evaporation). Experiments have shown that directly heating parts like seats, steering wheels, and armrests can improve heat transfer efficiency by 70% compared to air conditioning, prompting the ClimateSense system to restructure thermal management logic. The system employs 22 contact sensors and 14 Equivalent Uniform Temperature (EHT) sensors to form a wearable detection network, collecting real-time temperature data from 32 body areas. Using an algorithm model jointly developed with the Fraunhofer Institute, the subjective thermal comfort is converted into an objective Overall Thermal Sensation (OTS) value ranging from -3 (cold) to +3 (overheated), achieving a technological leap from an 'environment-centered' to a 'passenger-centered' approach.

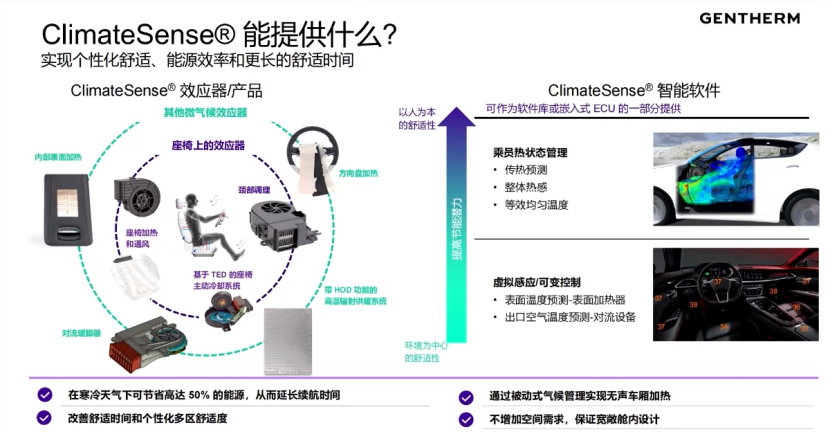

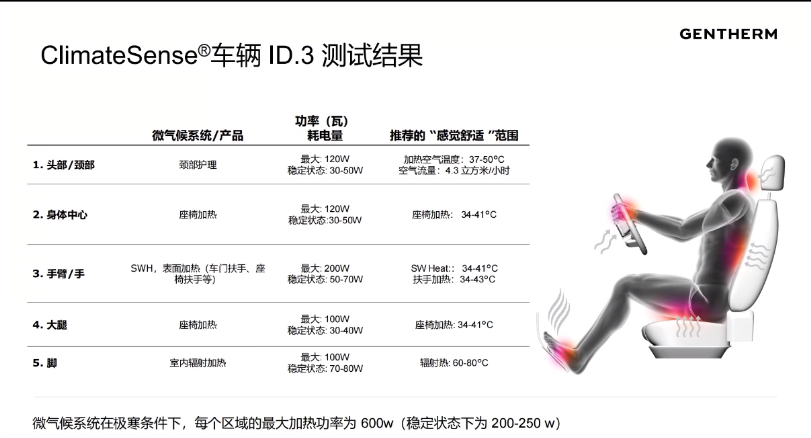

The ClimateSense system achieves precise temperature control through deep collaboration between the hardware and algorithm layers. The hardware layer integrates five-zone microclimate actuators, including a neck warm air collar (peak power 120W/steady state 30-50W), seat heating and ventilation (dual zone peak power 220W/steady state 60-90W), steering wheel heating (peak power 200W/steady state 50-70W), door armrest heating (peak power 100W/steady state 30-40W), and foot radiation heating (peak power 100W/steady state 70-80W), with a total peak power of 600W and steady-state energy consumption optimized to 200-250W.

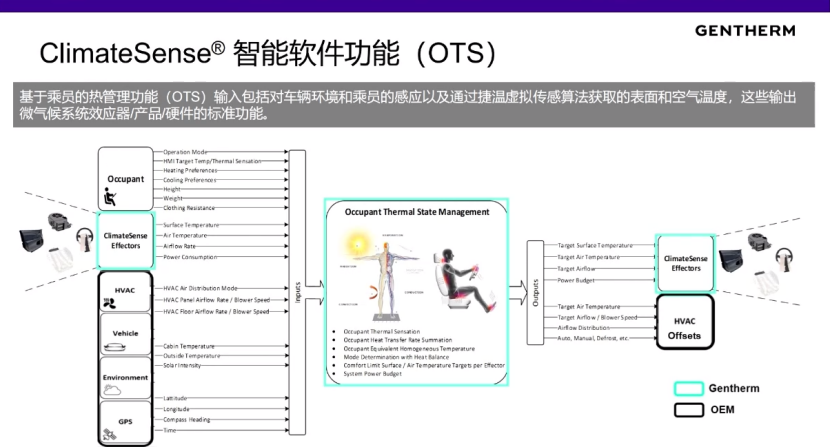

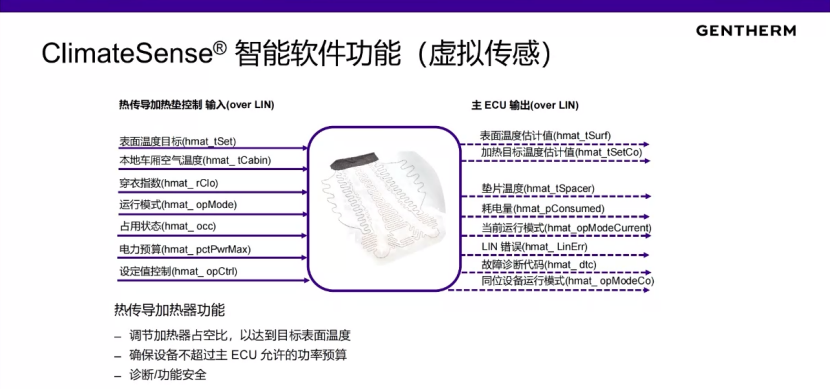

The algorithm layer innovates with virtual sensor technology, calculating the surface temperature of heating components in real-time based on a heat conduction model through the LIN bus (accuracy ±1-2°C), replacing physical sensors to reduce system complexity. Additionally, through the passenger thermal state management module, the system integrates vehicle environmental data (cabin temperature/sunlight intensity/geographical location), passenger physiological data (clothing index/target temperature setting), air conditioning parameters (air volume/air delivery mode), and actuator status to dynamically generate power allocation instructions with a refresh rate of 50ms, achieving closed-loop coordinated control of 33 actuators and the air conditioning system.

Real-world performance validation in a -7°C environment with the Volkswagen ID.3 model (testing duration of 30-60 minutes, collecting 3,000 sets of data) demonstrated dual breakthroughs in energy efficiency and comfort: in terms of energy efficiency, total energy consumption in a 60-minute operation was reduced by 30%, with average power in steady state dropping by 47% (from 6kW to 3.2kW), achieving a 50% energy saving over long distances; regarding comfort, the time taken to achieve passenger thermal comfort was shortened by 40% (reaching comfort standards within 5 minutes), with independent temperature control precision reaching ±0.5°C and over 90% correlation between OTS thermal sensation values and passenger subjective evaluations.

Testing verified three major advantages: personalized comfort (supporting front driver setting 22°C while rear passengers set 28°C), efficient energy use (prioritizing seat heating over air conditioning heating), and a quiet experience (maintaining comfort through radiation heating while turning off the air conditioning fan).

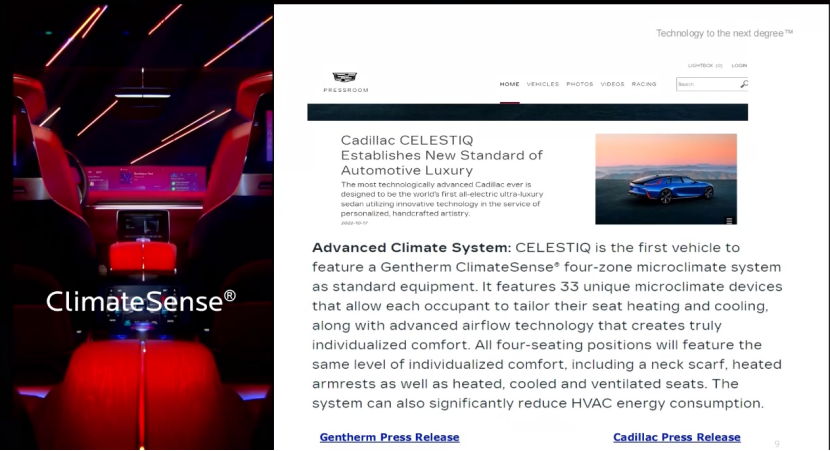

The ClimateSense system is now in mass production in vehicles like the Cadillac CELESTIQ (the world's first four-zone microclimate electric vehicle, integrating 33 actuators) and the ESCALADE IQ (a five-zone system supporting independent temperature control for all three rows), setting a new standard for thermal management in luxury electric vehicles. The next phase of the industry needs to overcome three major challenges: reducing multi-actuator coordinated response time to within 100ms to meet L4 autonomous driving safety requirements; designing a compact system to fit space constraints in compact vehicles (currently, the module volume is about 12L); and improving the generalization ability of data models across climate zones (covering a full range from -30°C to 50°C).

Gentherm emphasizes that the future will transition from Auto AC (automatic air conditioning) to Auto Thermal Management (passenger thermal management), achieving ultimate goals of unified scheduling of air conditioning, seats, steering wheels, and other thermal components for automatic adjustment to achieve 'one-button comfort' for each passenger.

Advancements in Thermal Management Technology for New Energy Vehicles

Images

Share this post on: